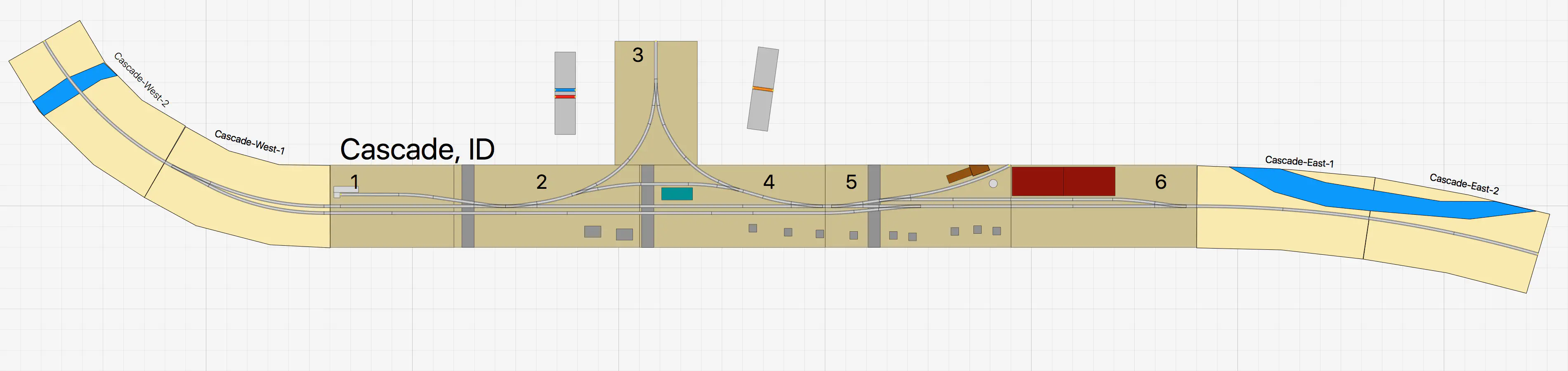

Module: Cascade, ID

By hagen

Cascade, Idaho. Is consists of eight segments and has a total length of about six meters. It has three industry tracks with a total of about 14 spots, a three meter long passing siding and a wye to connect a to a branch or turn trains.

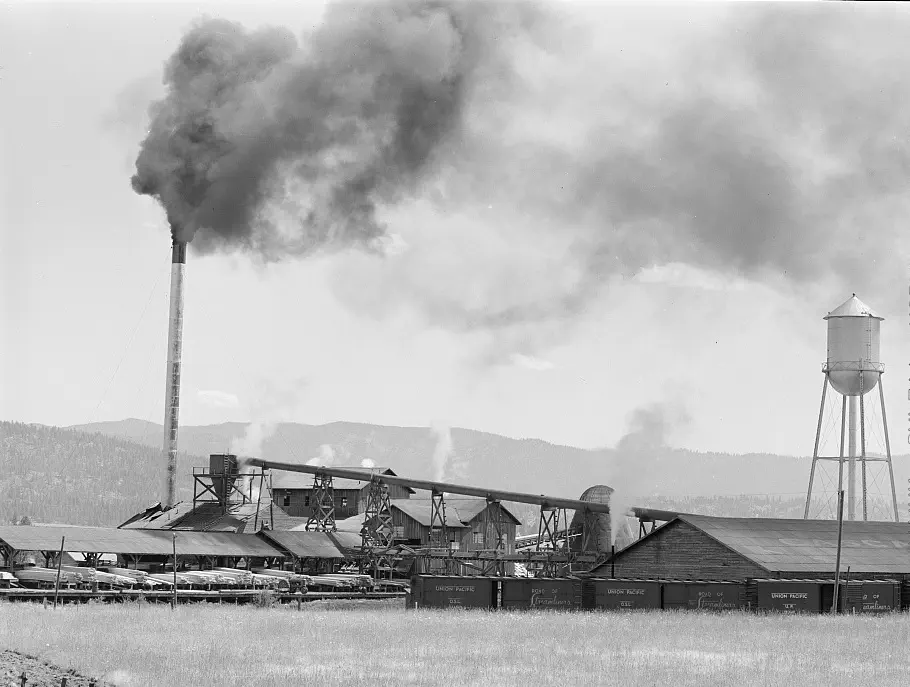

The prototype

The Module

Switching Cascade

The module It has four spurs with spots to be served but not every spot is served every day. No matter what direction your train is coming from, one of the spurs is always facing you. Thus you have do a run a round move or – if working on a turn – serve it on the way back.

The Industries

Team Track

House Track

Hallack & Howard Lumber Company

How it all came into beeing

It took about three years to build and complete this module. You can read more about the construction module in my Building-Cascade series.