Building Cascade 7: Going fency

Due to the selected level of compression, the lots are smaller – most of all shorter – than in the prototype. But even in the prototype some of the lots are quite narrow and accommodate a small house and a garage. I wanted to capture this look and feel and found some kits, that would help me to achieve that.

The smallish house with the garage is Kit No. 698 “Company House” by American Model Builders. The fence is RsLaserkits No. 3505. I forgot which kit I used for the shed but the neighbour to the right is the “One story section house” Kot 629 by American Model Builders.

Building Cascade 6: Renovation required

Opposite of the Cascade Depot there are multiple lots with either small business or private structures. The houses in Cascade near the railroad tracks are an interesting mix. Most of the houses are quite unique and do not repeat along the street. A few years ago I bought a few laser kits for different houses. Some of the kits either contained two or three samples of the same house or I simply bought multiples of them. So I had a good stock of parts to kit bash a nice variety of houses for my module.

Building Cascade 5: The Lumber Warehouse

The Hallack & Howard Lumber Company Sawmill is the main industry in Cascade and on my module. It has two tracks and generates about 6 to 9 cars incoming and outgoing traffic every day. Let me show you, how it was built.

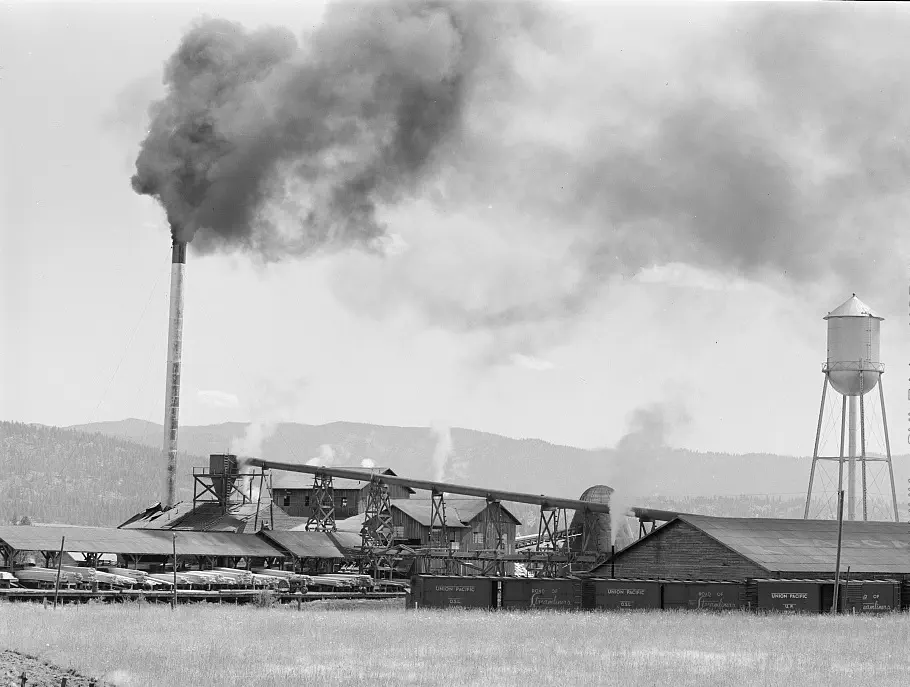

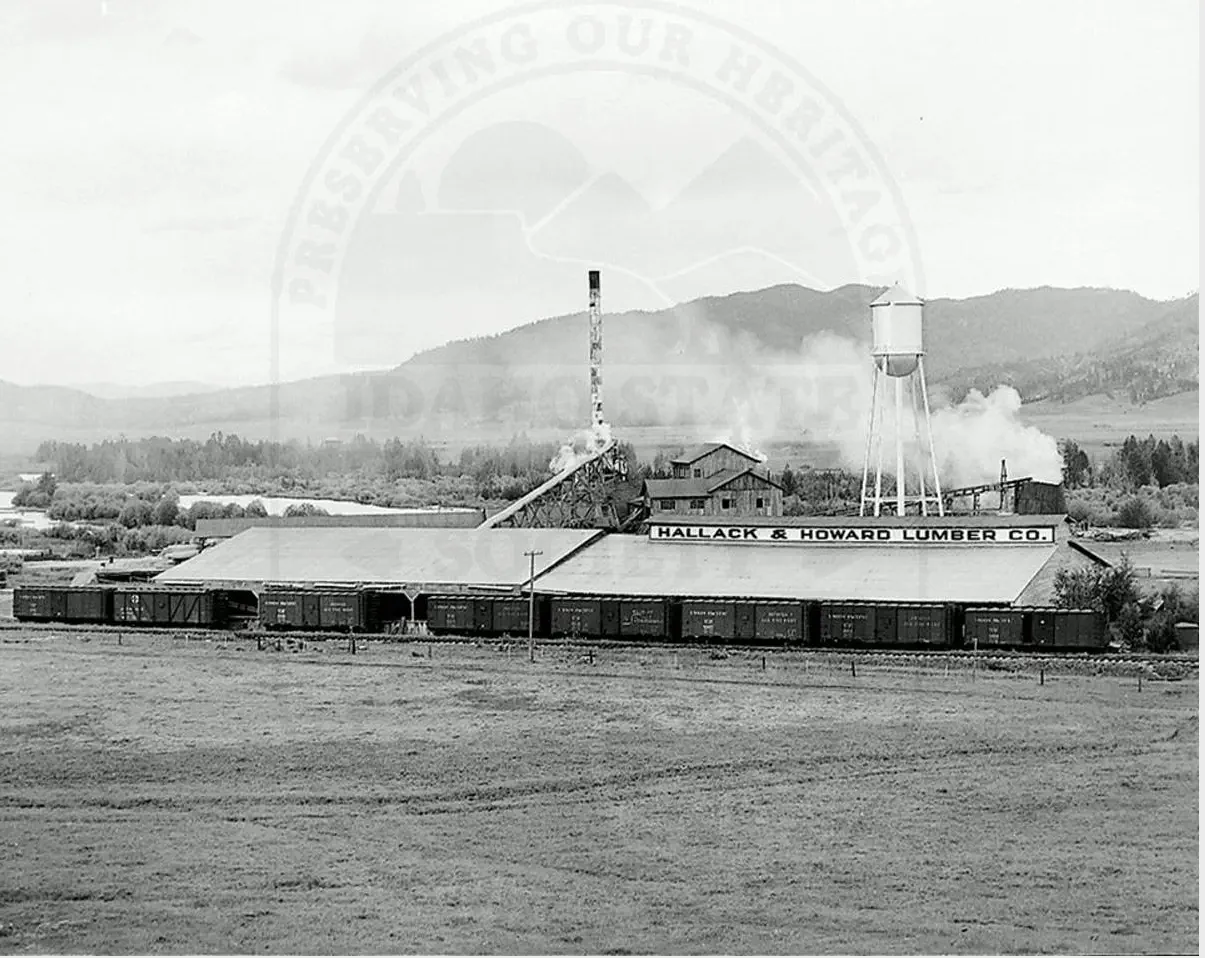

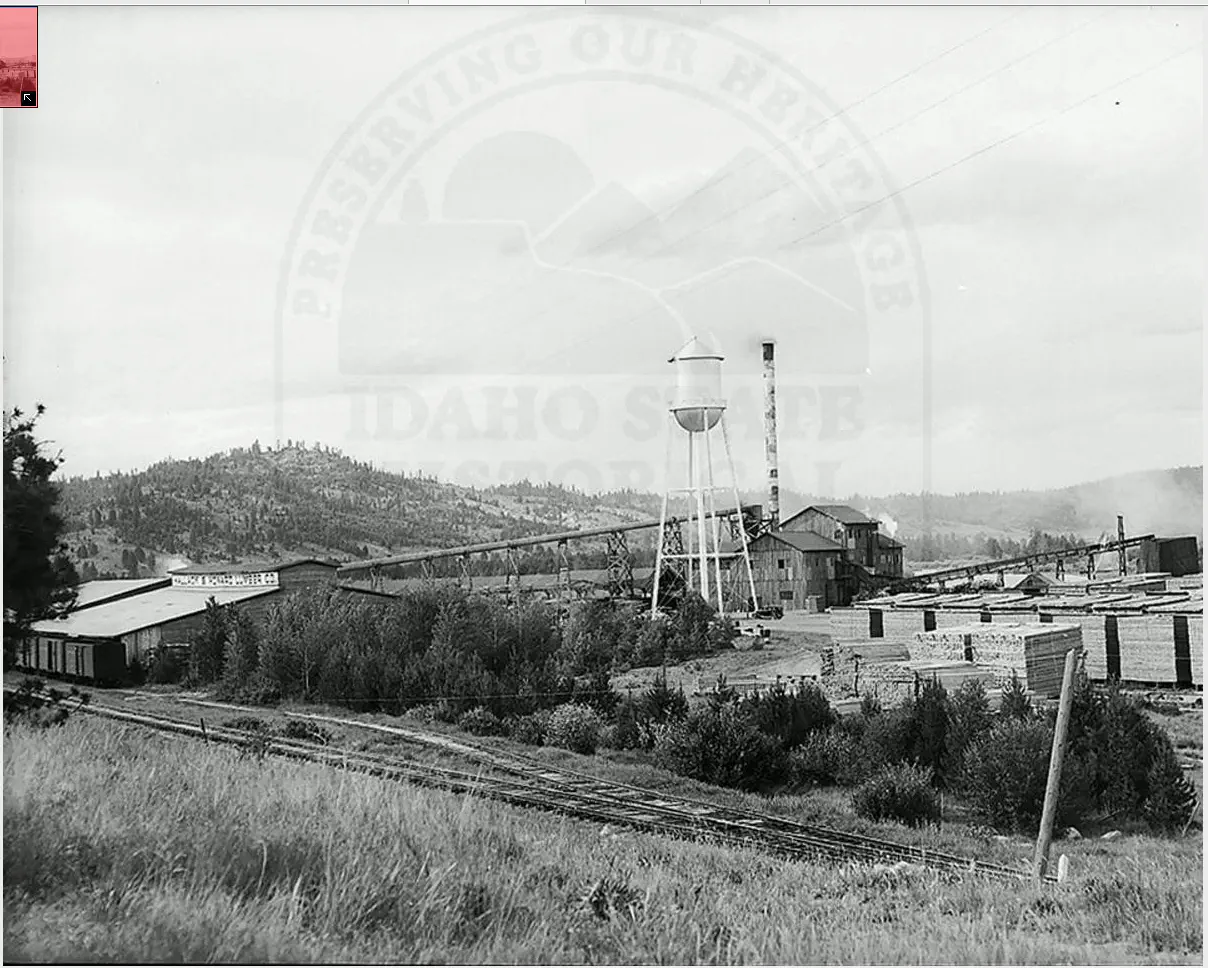

Hallack & Howard Lumber Company

Hallack & Howard Lumber Company, Images LOC & Idaho State Historic SocietyThe sawmill was torn down, but in the 1960s it was quite busy and is the main industry on my module. So I wanted to build the warehouse. I found very few photos I could use as a reference. During the early build of the module I had prepared an area for the warehouse. The structure should come as close to the prototype as possible, without exceeding the determined space on the module.Building Cascade 4: The Depot

I wanted to capture the look of the prototype as close as possible but I could not find any kit that came close enough. So I decided to create the depot my self. I constructed it in 3D CAD and got it printed by Shapeways.

The Depot was built in 1914 for the Oregon Shortline Railroad. It functioned as a freight room, baggage and ticket office, and waiting room as well as a second story home for the station agent. It was moved from its original site in 1986.

Building Sussex 9: Painting the pit

With only a few weeks to the exhibition in Rodgau, I wanted to give the flooded quarry pits a nice prototypical look: Turquoise.

In the last step multiple coats of glossy varnish are added. The varnish does not have to be too smooth as there surface of the water might show some ripples.When I sprayed the bottom of the pit I did not cover the walls and that resulted in an overspray. I have not yet decided whether I will remove it or keep it. Currently I kind of like it. I like how the walls are colored by “reflections” or “glow” of the water. Maybe I’ll remove it sometime later but for now I’m happy with the result.Building Sussex 7: WBS Warehouse 1

There are two buildings on the Wisconsin Building Supply (WBS) lot, that visible in the modelled section. Right behind the fence, near the WBS spur is a “small” warehouse. It has a simple shape and is not too hard to build. Only drawback: It is positioned right above the joint of two modules, so it has to be removed for transport and storage.

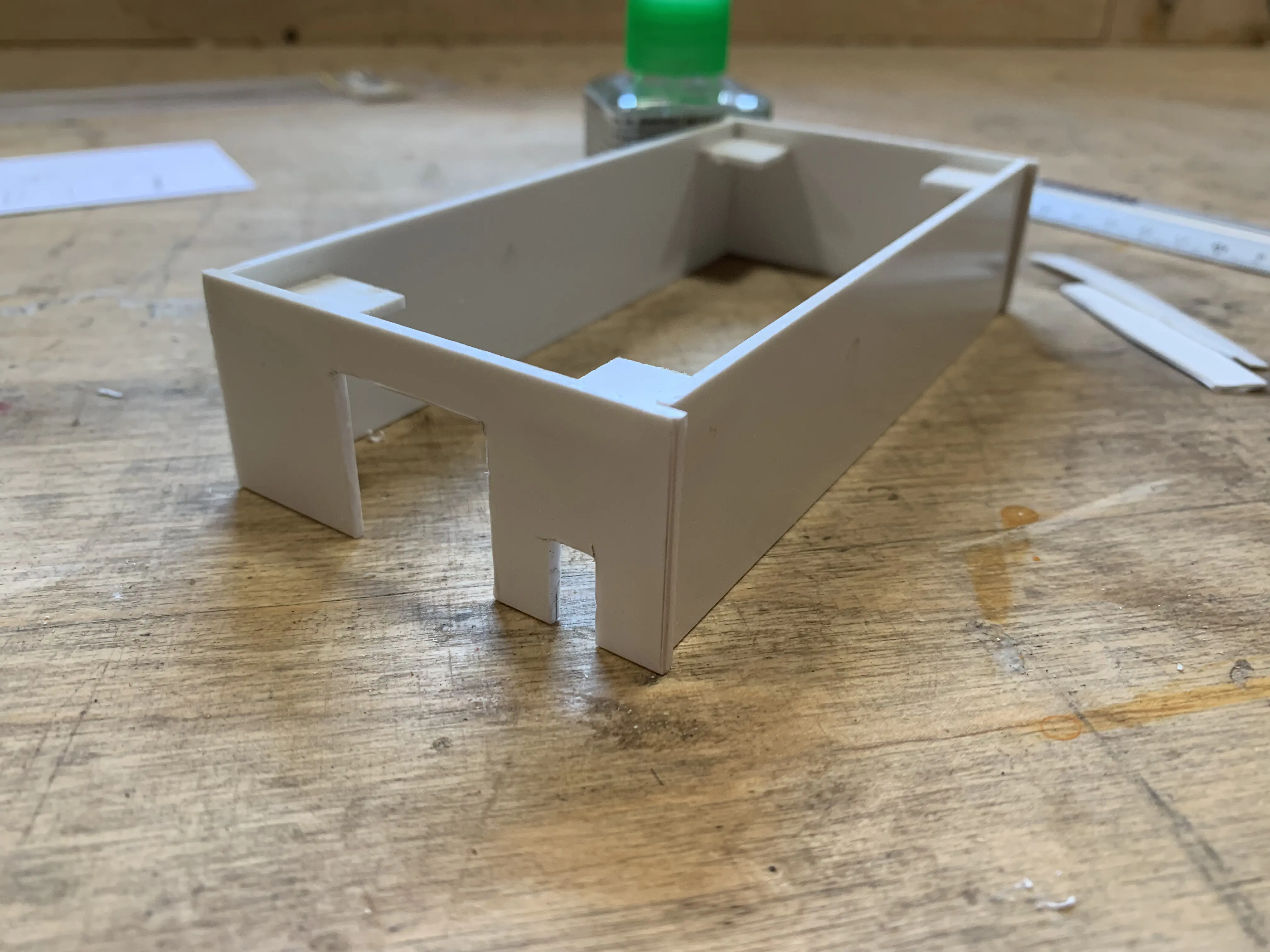

Building Sussex 6: WBS Ramp

When I studied the satellite imagery of the area, I noticed that there is a ramp near the track on the lot of Wisconsin Building Supply. I was surprised. I had not noticed it before. But I like the idea. This makes a great spot for a second car that can be delivered there.

To build the ramp, I took measurements in Google Earth. The ramp seems to be built of concrete. The wall pointing away from the track is higher as a safety measure to prevent fork lifts to drive off the ramp. Some steel plates are lying on or near the ramp to cover the gap between the ramp the rail car.

Fun-Testing weekend: Small modular meeting at Delmenhorst 2019

July 2019 in Delmenhorst, Germany. It was one of the warmest days of the year some maniacs had no better idea than setting up a modular layout for the weekend.

In October 2019 we want to show a layout during the US-Modellbahn-Convention in Rodgau. In the FREMO americaN group we build modules for operations. Showing the modules at an exhibition or convention is not our primary intention, but we found out that we could build an oval layout with some modules and only needed two small adapters to make it all fit. That’s what we did. Dirk extended his fiddle yard (Parkwater) to a length of six meters. Additionally he built a frame to hide the yard between to six meter long backdrops Peter created and had printed on truck tarpulin. My job was simple: finishing my six meter long module Cascade and build all required structures. No big deal ;o)

Workshop-Weekend 2019: Scenery

We need more coffee.

We wanted to make another Workshop-Weekend. Because its fun, you can learn new stuff and get something done. And there is enough coffee. As there are still modules left with plywood pacific from last years Workshop-Weekend we wanted to build scenery this time.

Cardboard-Grid and Plaster

Everyone worked on his modules or built scenery details. Dirk worked on a simple straight line module. He added the scenery by the classic cardboard-grid method. He glued cardboard strips to the module with hot glue. The this grid was covered with strong paper. For the next layer Dirk used plaster dressings. When the plaster was solid, a layer of flexible joint filler in beige was added. This makes the base for all following steps.

Workshop Weekend 2018

Last year, Dirk offered his garage for a Workshop Weekend. This year I left my workbench at home and Invited my friends to spent some time drinking coffee, eating pizza and build modules. We agreed on building only line modules. This time we really did so. Peter and I had discussed the idea of a duck under to make it easier to move to the opposite side of the modules. In total we built 22 new modules or segments of modules.