Building Sussex 7: WBS Warehouse 1

By hagen

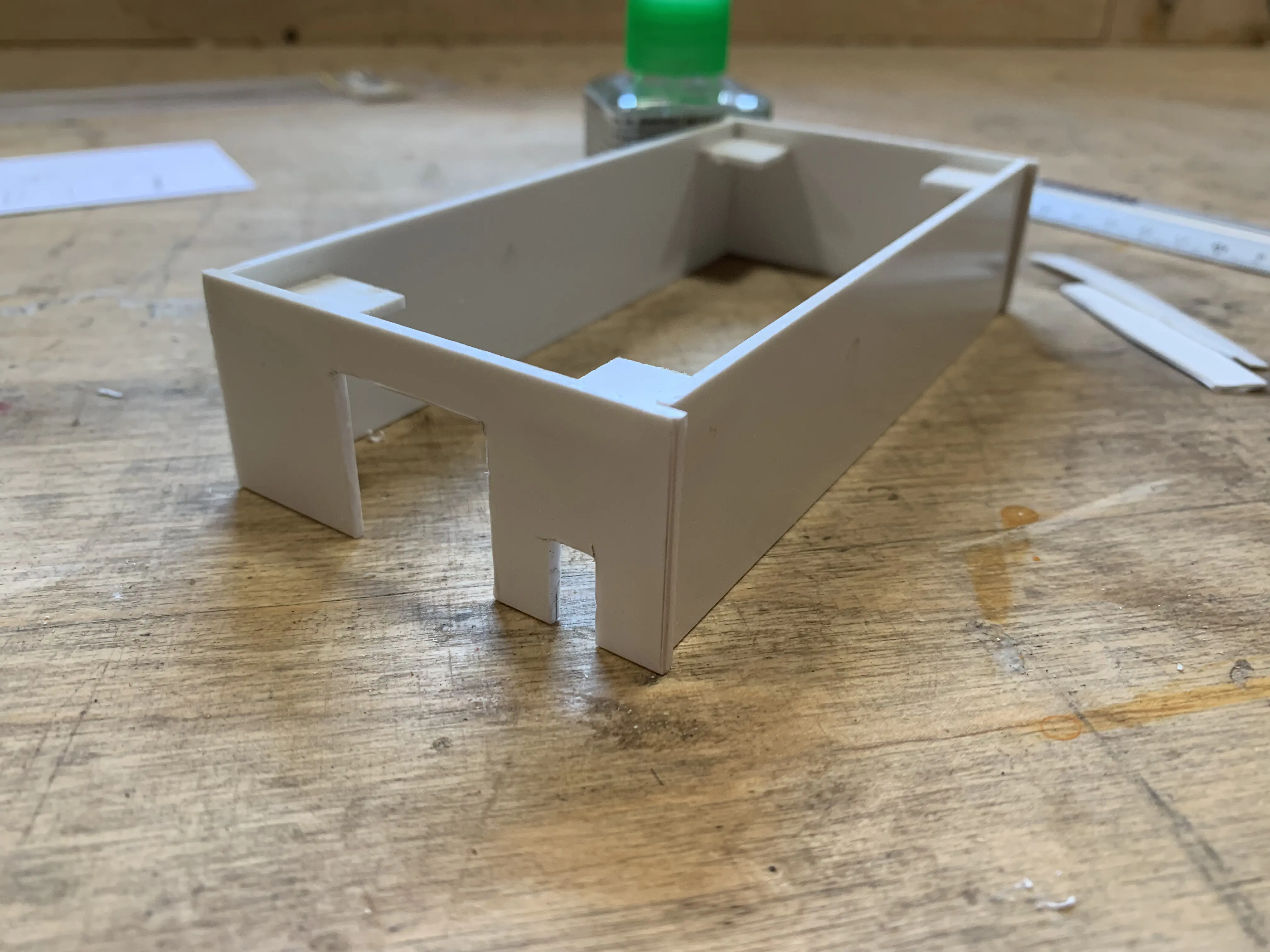

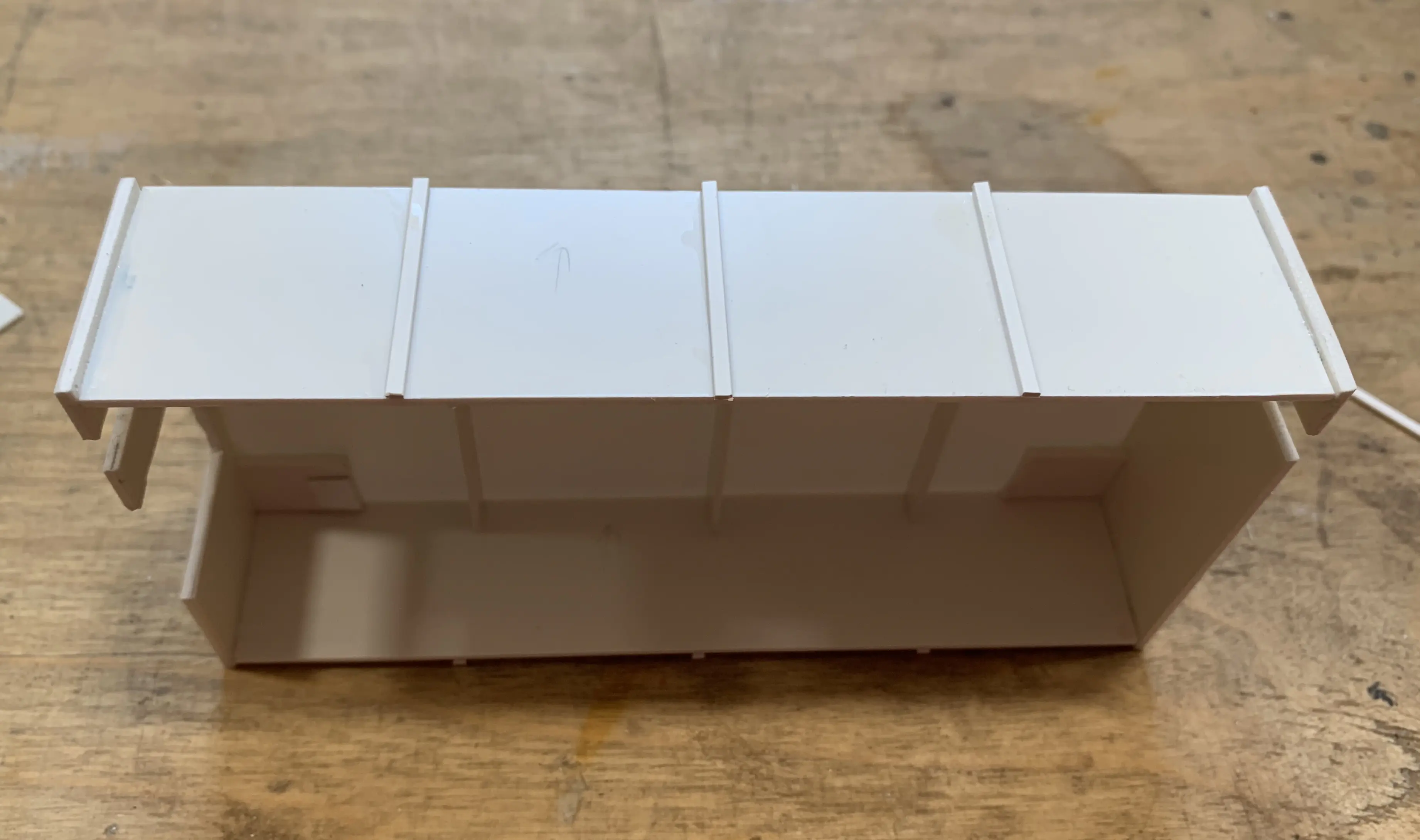

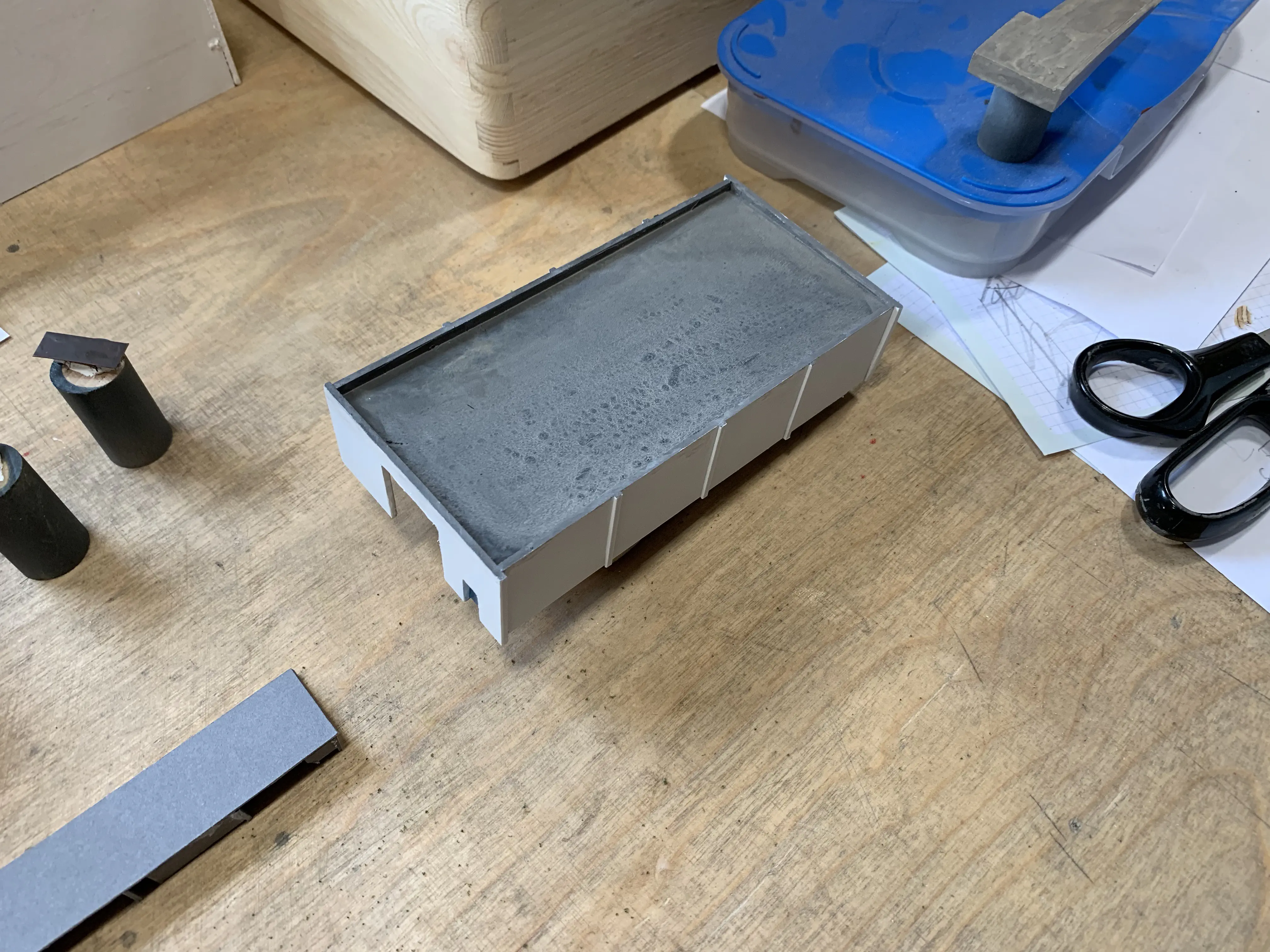

There are two buildings on the Wisconsin Building Supply (WBS) lot, that visible in the modelled section. Right behind the fence, near the WBS spur is a “small” warehouse. It has a simple shape and is not too hard to build. Only drawback: It is positioned right above the joint of two modules, so it has to be removed for transport and storage.

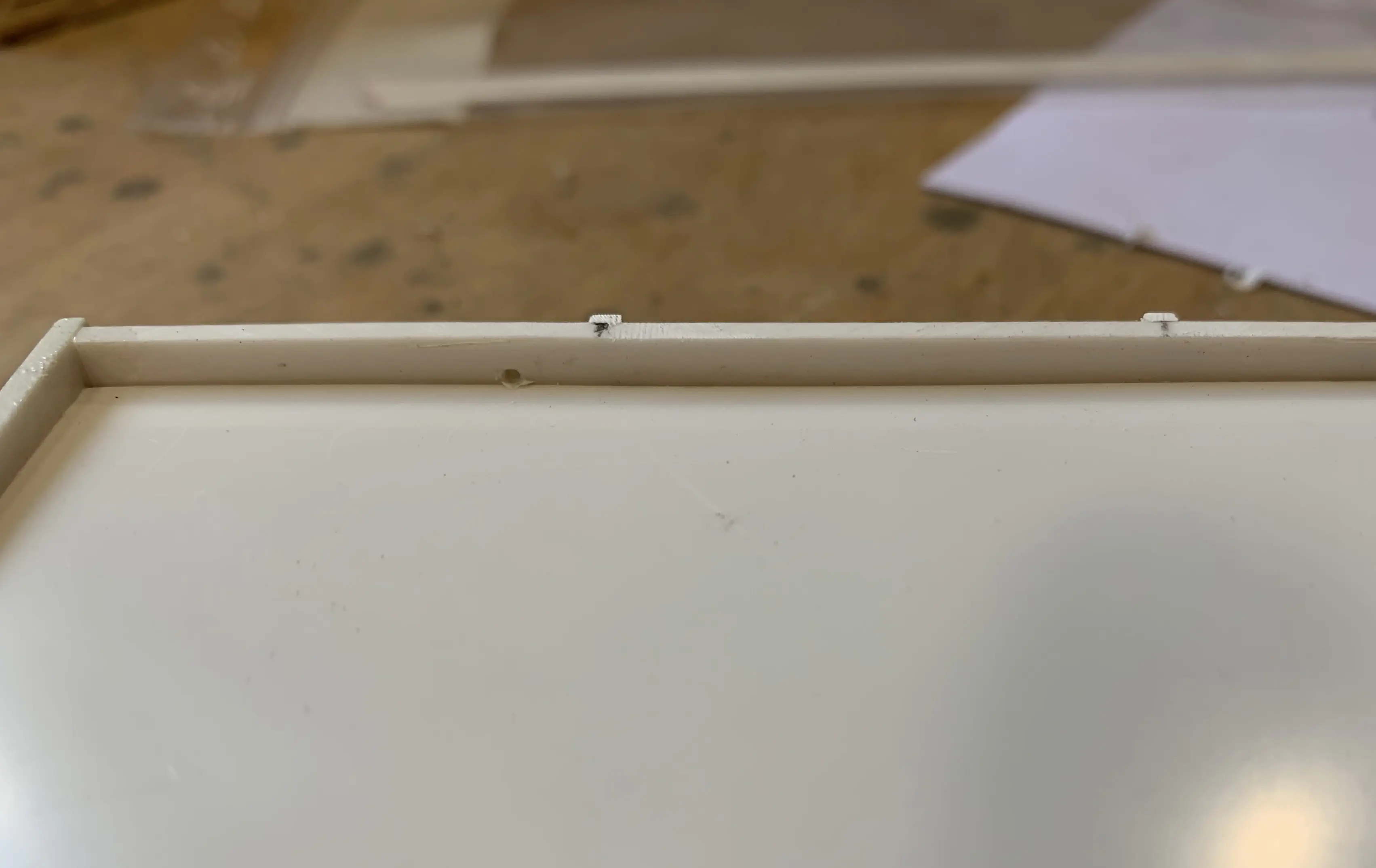

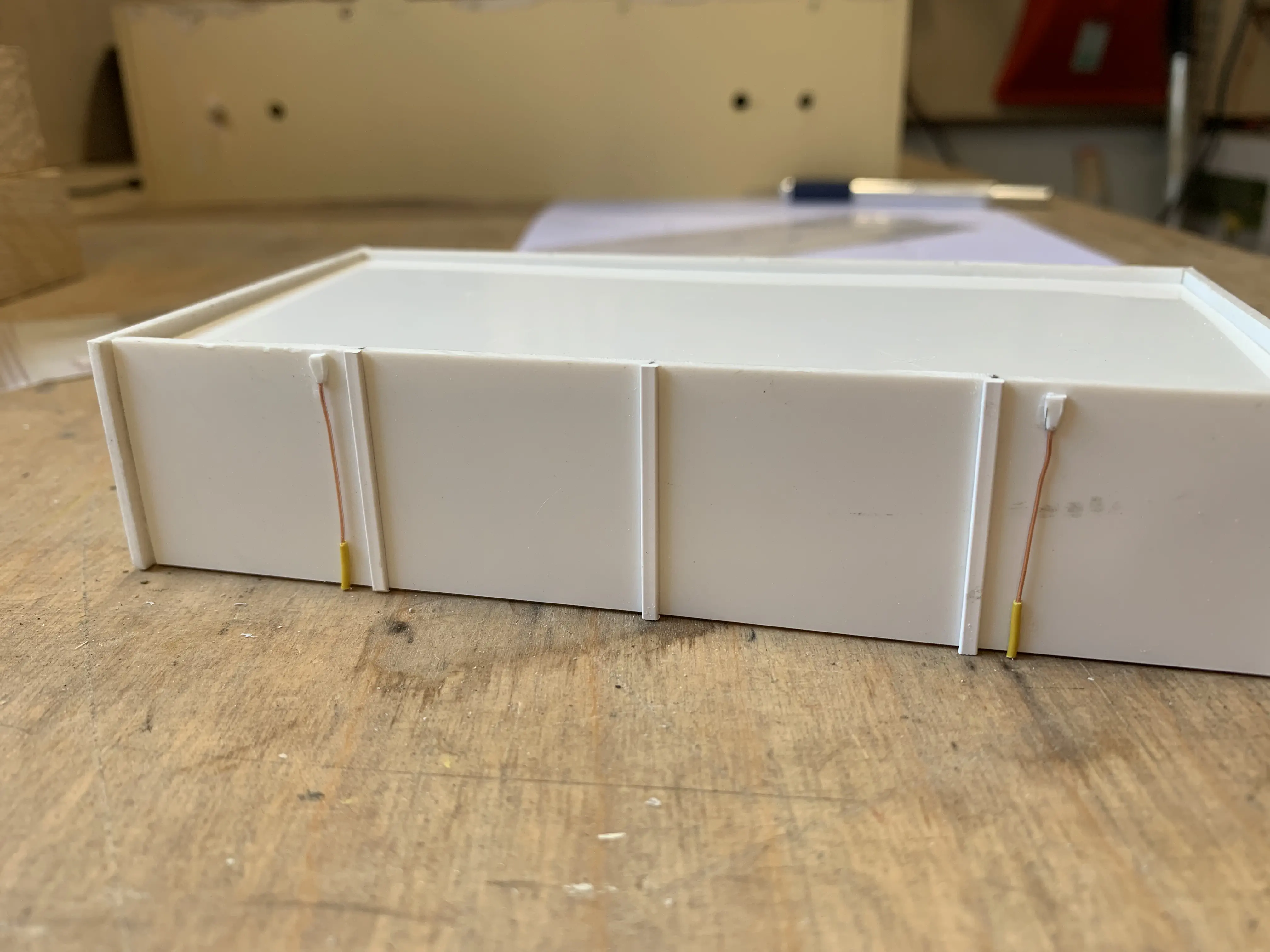

Rainwater pipe installed.I carved the connections for the rainwater pipe out of some left over bits of styrene. I choose 0,5 mm² wire as a pipe. Thats slightly too thin, but the closest I could get with the available material. To attache the “pipe” a 0.5 mm hole was drilled into the spout. The insulation was left on the wire at the very bottom to show the connection to the underground sewer.

For the installation I added two small magnets to the inside at opposite corners and matching magnets to the module. Some guides are installed on the module to ensure correct positioning and preventing the building from being shoved away from magnetic mounts. Of course I forgot to take a picture of the finished setup.

Read more about the progress in my Building-Sussex Series.