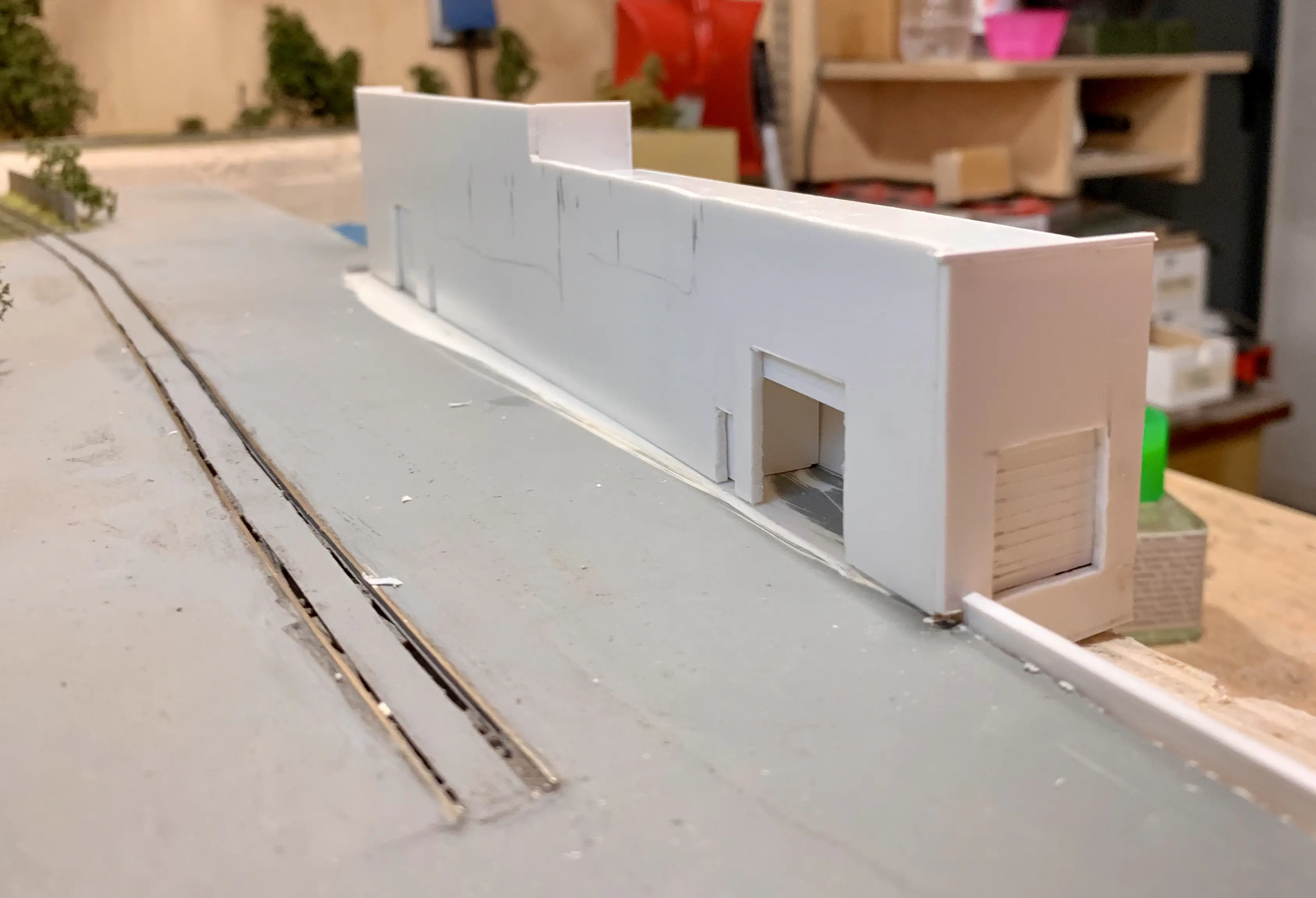

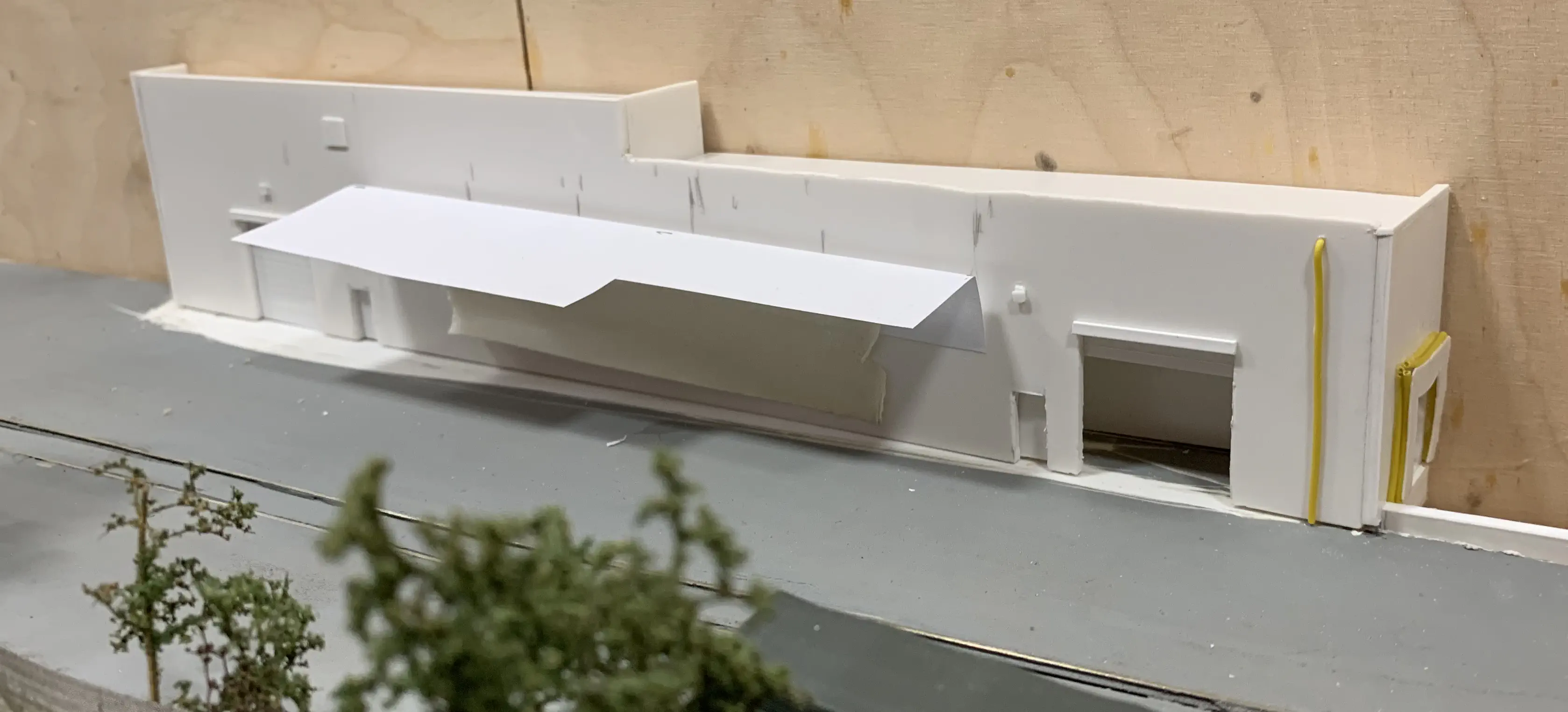

Building Sussex 8: The Warehouse

By hagen

There is a large warehouse on the property of Wisconsin Building Supply in Sussex (WBS). If I would model the scene exactly to scale, I wouldn’t have to bother with it. But I wanted to have it on the module and moved it closer to the rails.

Read more about the progress in my Building-Sussex Series.