Building Cascade 5: The Lumber Warehouse

By hagen

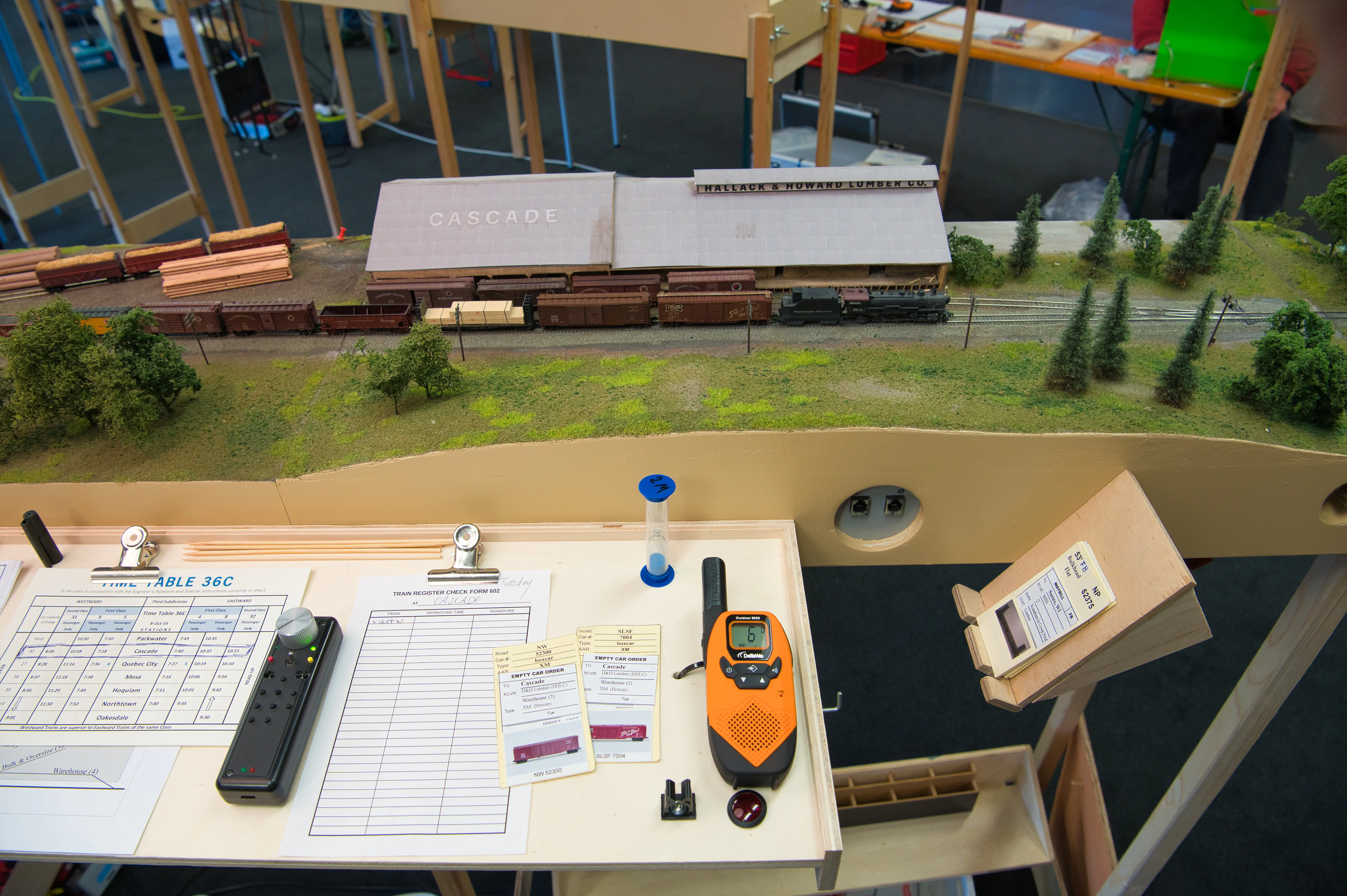

The Hallack & Howard Lumber Company Sawmill is the main industry in Cascade and on my module. It has two tracks and generates about 6 to 9 cars incoming and outgoing traffic every day. Let me show you, how it was built.

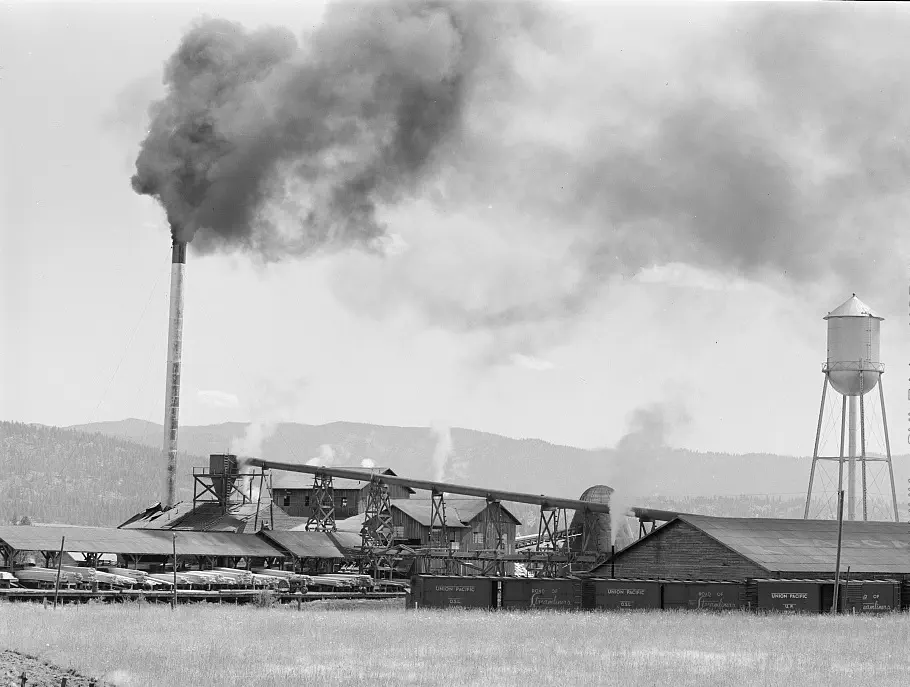

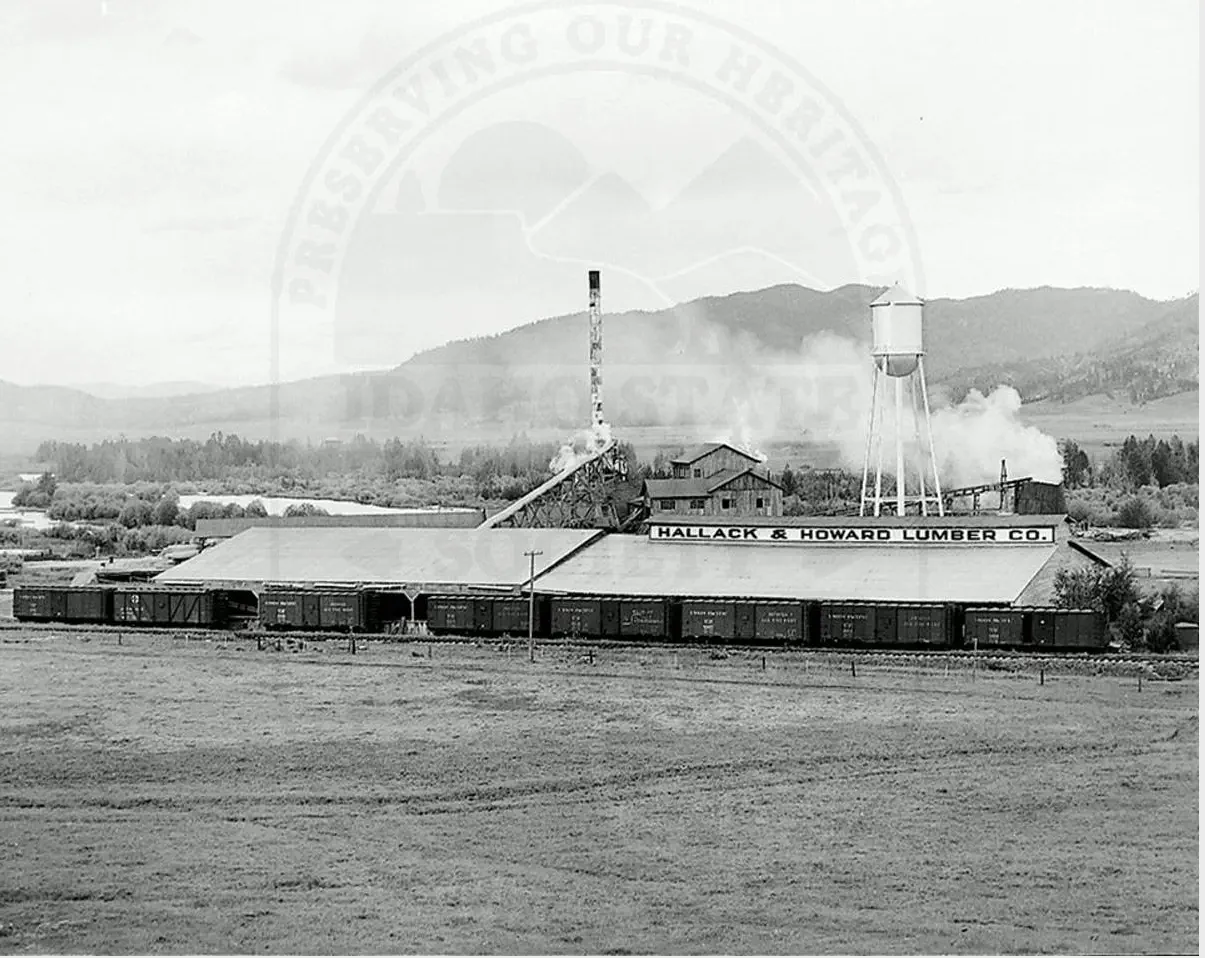

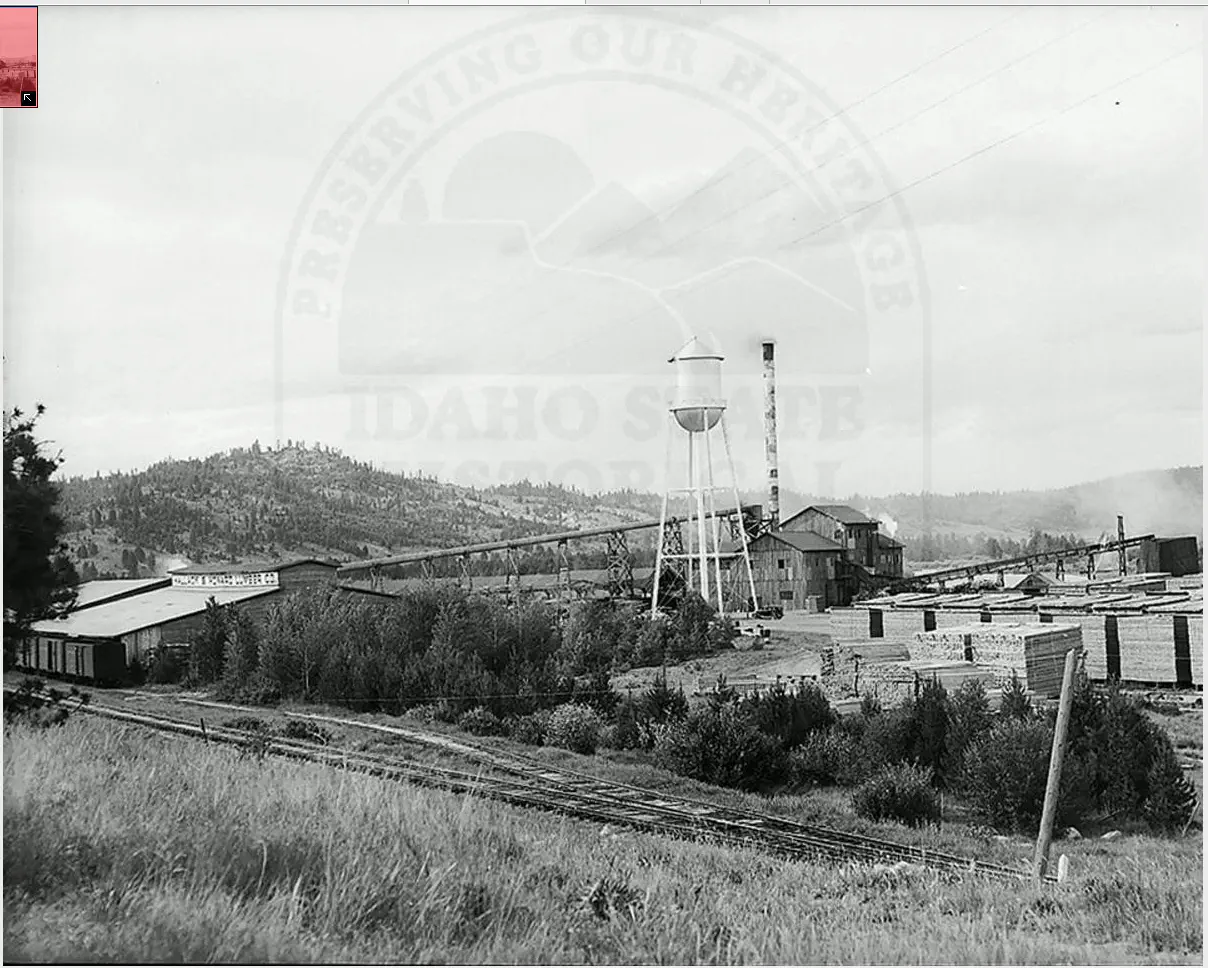

Hallack & Howard Lumber Company

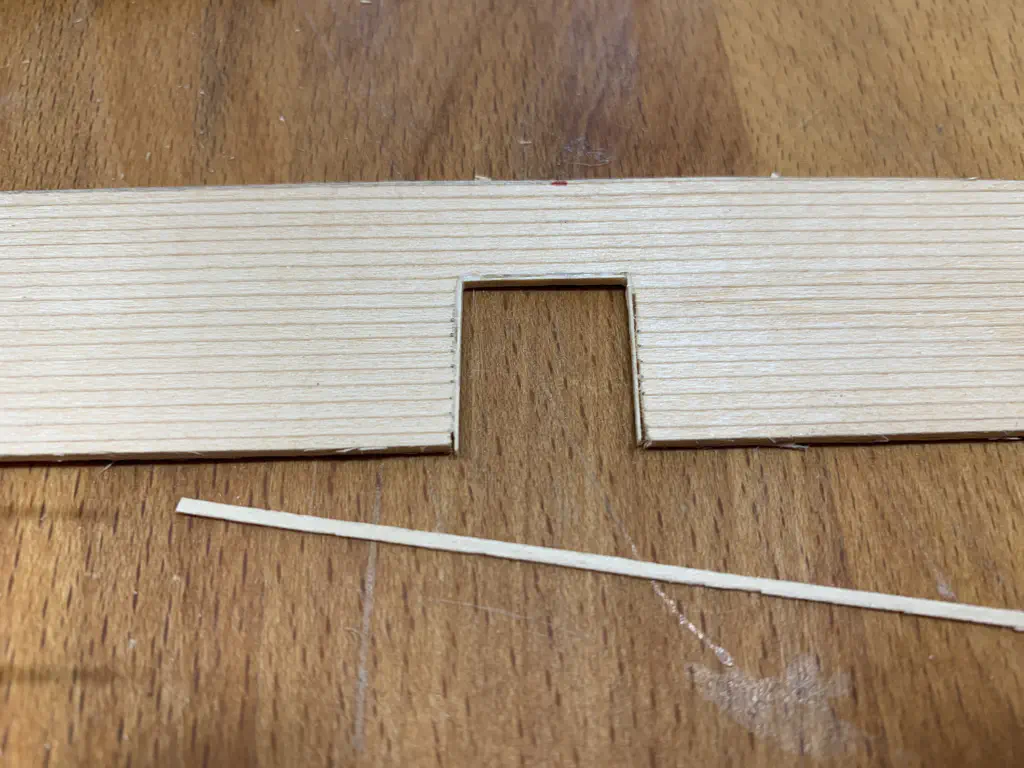

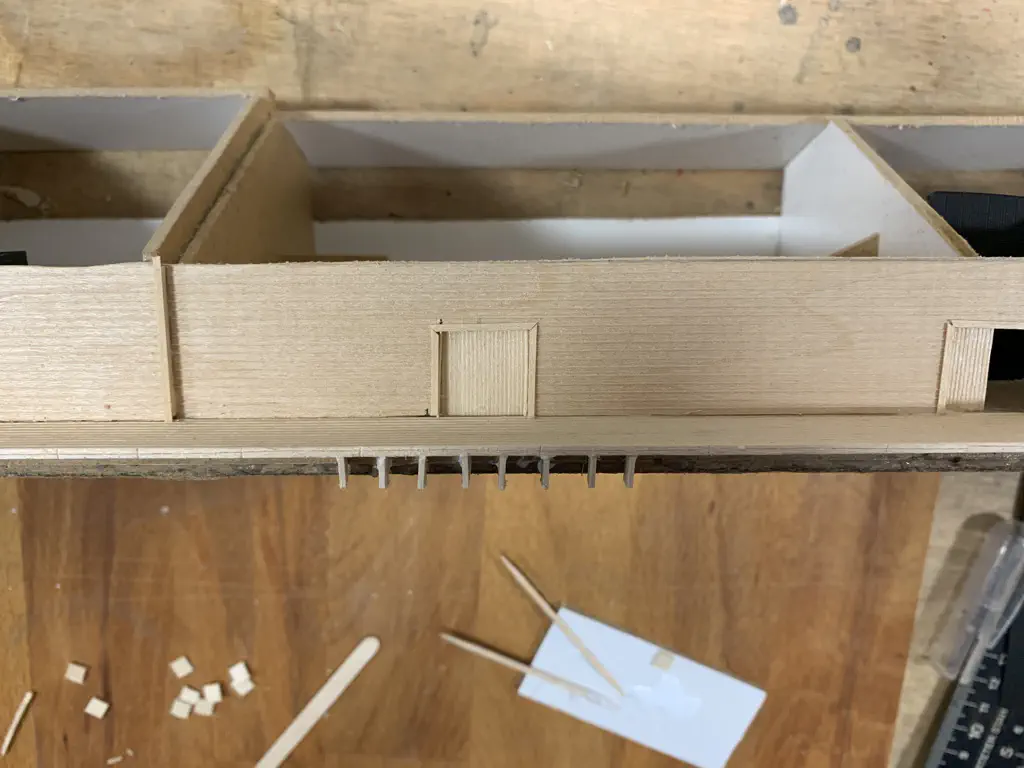

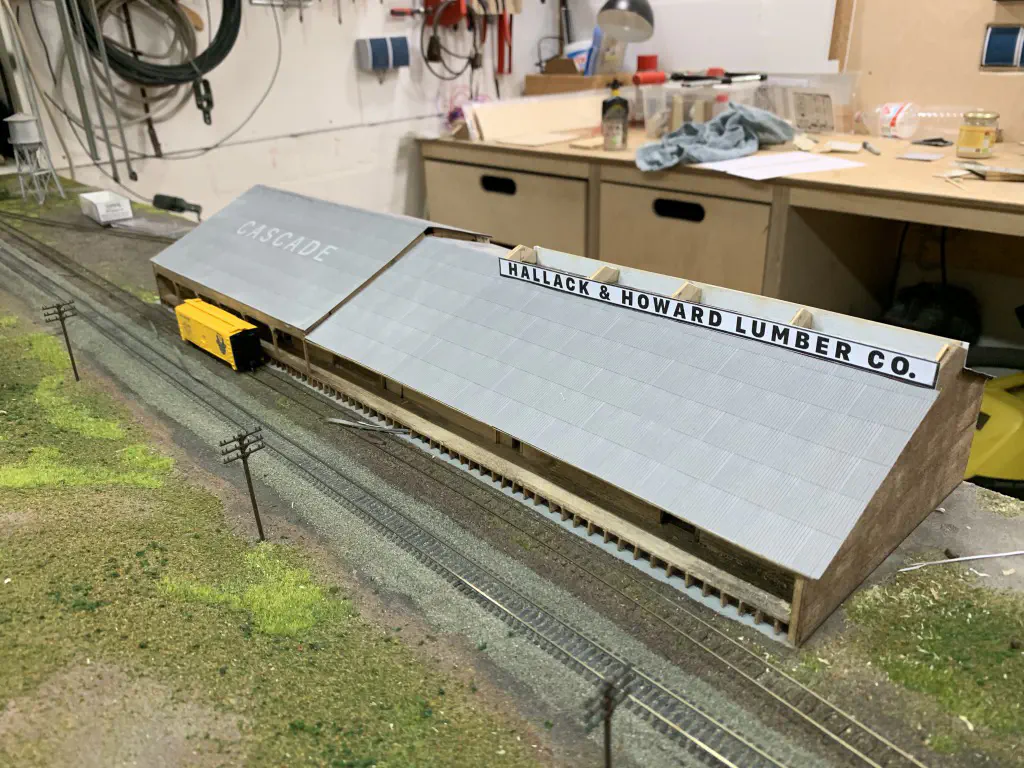

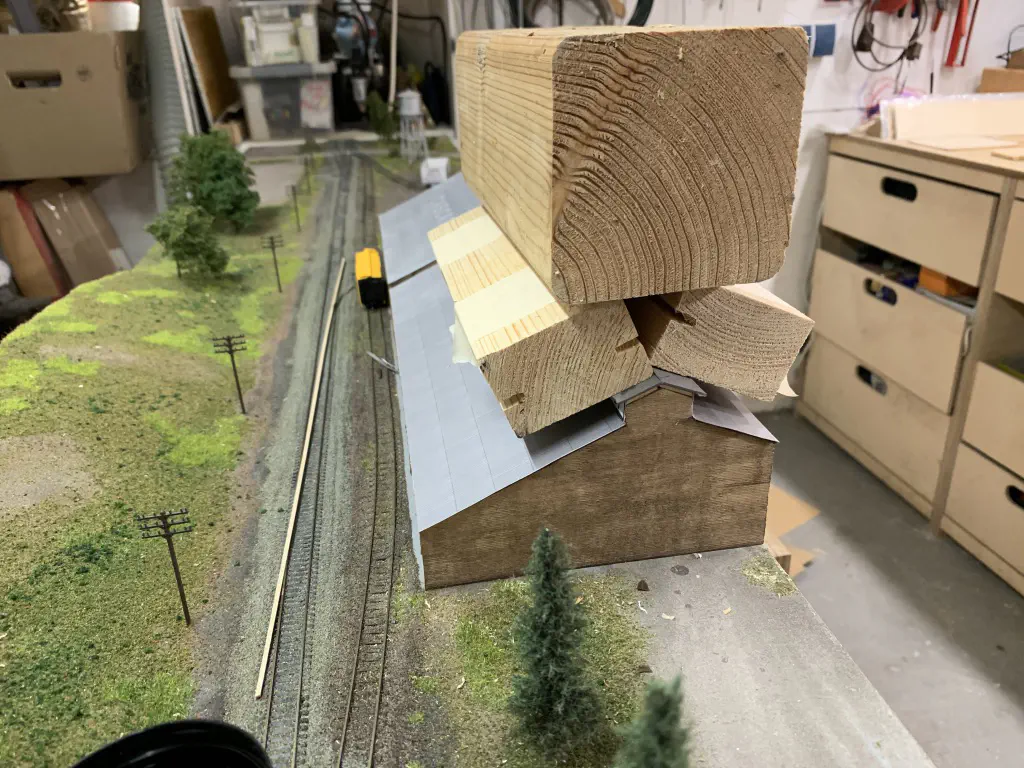

Hallack & Howard Lumber Company, Images LOC & Idaho State Historic SocietyThe sawmill was torn down, but in the 1960s it was quite busy and is the main industry on my module. So I wanted to build the warehouse. I found very few photos I could use as a reference. During the early build of the module I had prepared an area for the warehouse. The structure should come as close to the prototype as possible, without exceeding the determined space on the module. First I had to extend the side wall of the module to acts as a wall for the structure.I figured out I could build the warehouse with length of about 56 cm and a total width of 30 cm, truncated to about 17 cm. That depicts a structure that is about 90 m long and 48 m wide and should come quite close to the prototype as it has been in the 1940s.The building is built around a core of 4 mm masonite, wich is covered with sheets of scale lumber. The structure has a base of two sheets of masonite, to reach the correct height for the loading dock. A rear wall, side walls and some vertical frames were glued to the base. None of these would remain visible. I added some blocks of plywood to the base and drilled holes trough the blocks, base and into the top of the module. The finished building will be held in place by a pair of screws.

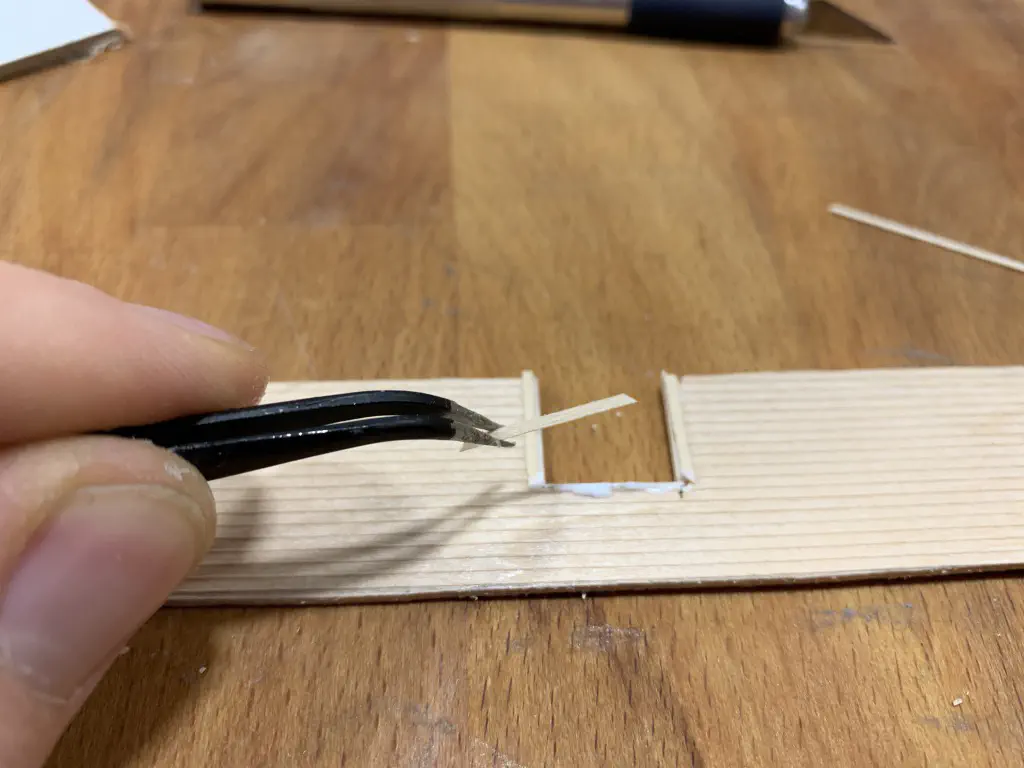

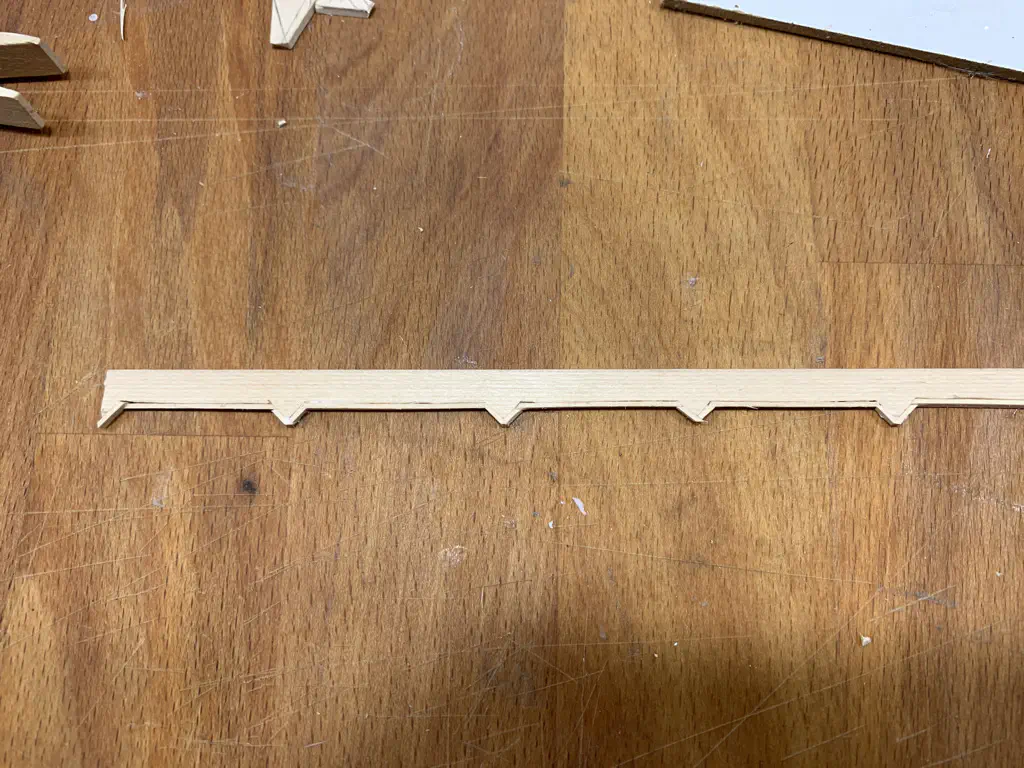

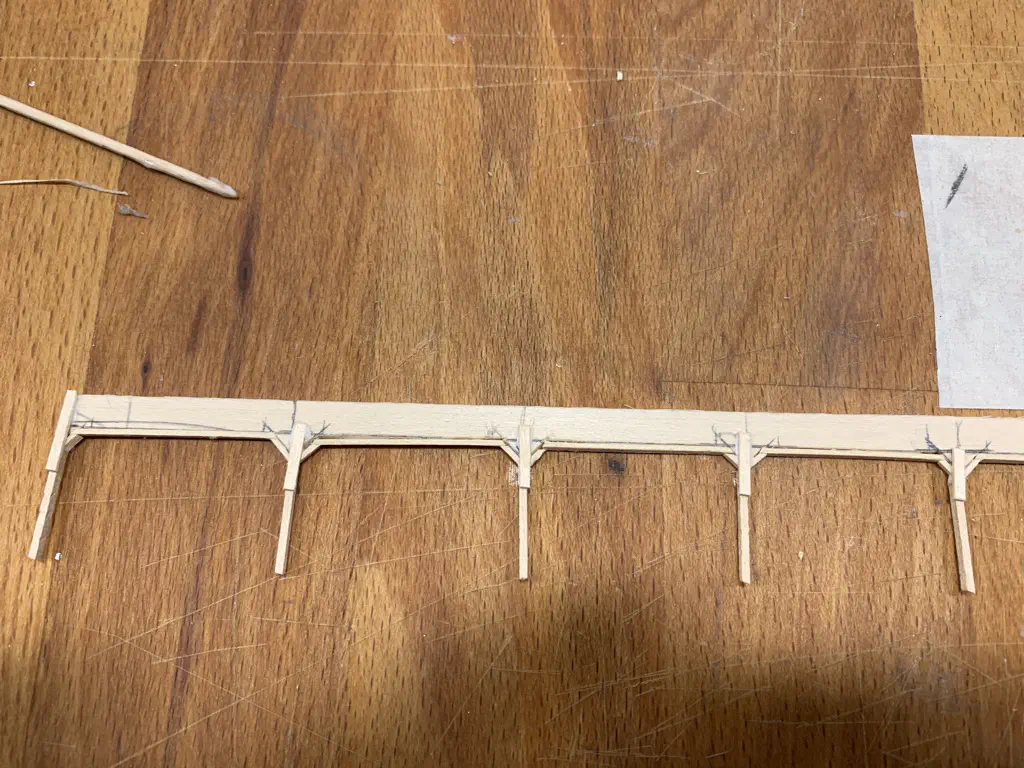

It seems as if the warehouse has been extended during its use and the extension slightly differs from the first part. A part of the loading dock has supports for the roof while the – I guess newer – part does not. There you can see the ends of the beams supporting the roof. So I built a wall with separately applied supports for the older part and added beams to a piece of cardboard for the newer segment. Sometimes I tend to forget the tortures I put myself in. All visible wood faces were treated with a mix of isopropanol and indian ink. At least two applications were required to reach the weathered look I was after.

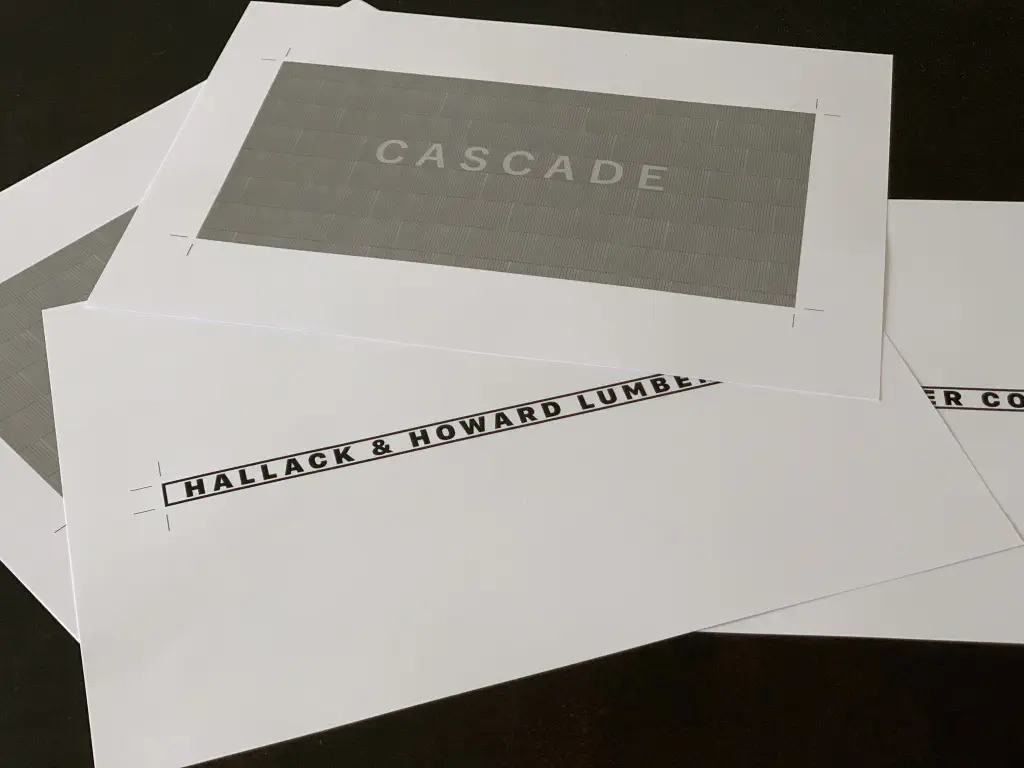

The roof is covered with corrugated steel, which I printed – 2D only. I found a photo that clearly shows “Cascade” written onto the roof. So I created the roof in Photoshop and added the text to the corrugated steel. The masonite core did not support the whole roof, thus I added a layer of cardboard to the roof. The printed roof sheets where cut to size and glued onto the cardboard. The right part of the roof has an addition – I guess for ventilation – which is labeled with the name of the company. To build this component was a bit tricky, if not annoying. But is a key feature of the building and I got it done.

Sawmill warehouse during construction.Just in time to the US Model Railroad Convention 2019 in Rodgau I was finished. I made my colleges slightly nervous with working so close to the dead line, but It was finished in time. Hallack & Howard Lumber Company Warehouse finished and operating.See more progress in the Building Cascade Series.