FREMO americaN Operations

This article gives an insight into the operationional concept for a typical modular meeting of the americaN chapter of the FREMO.

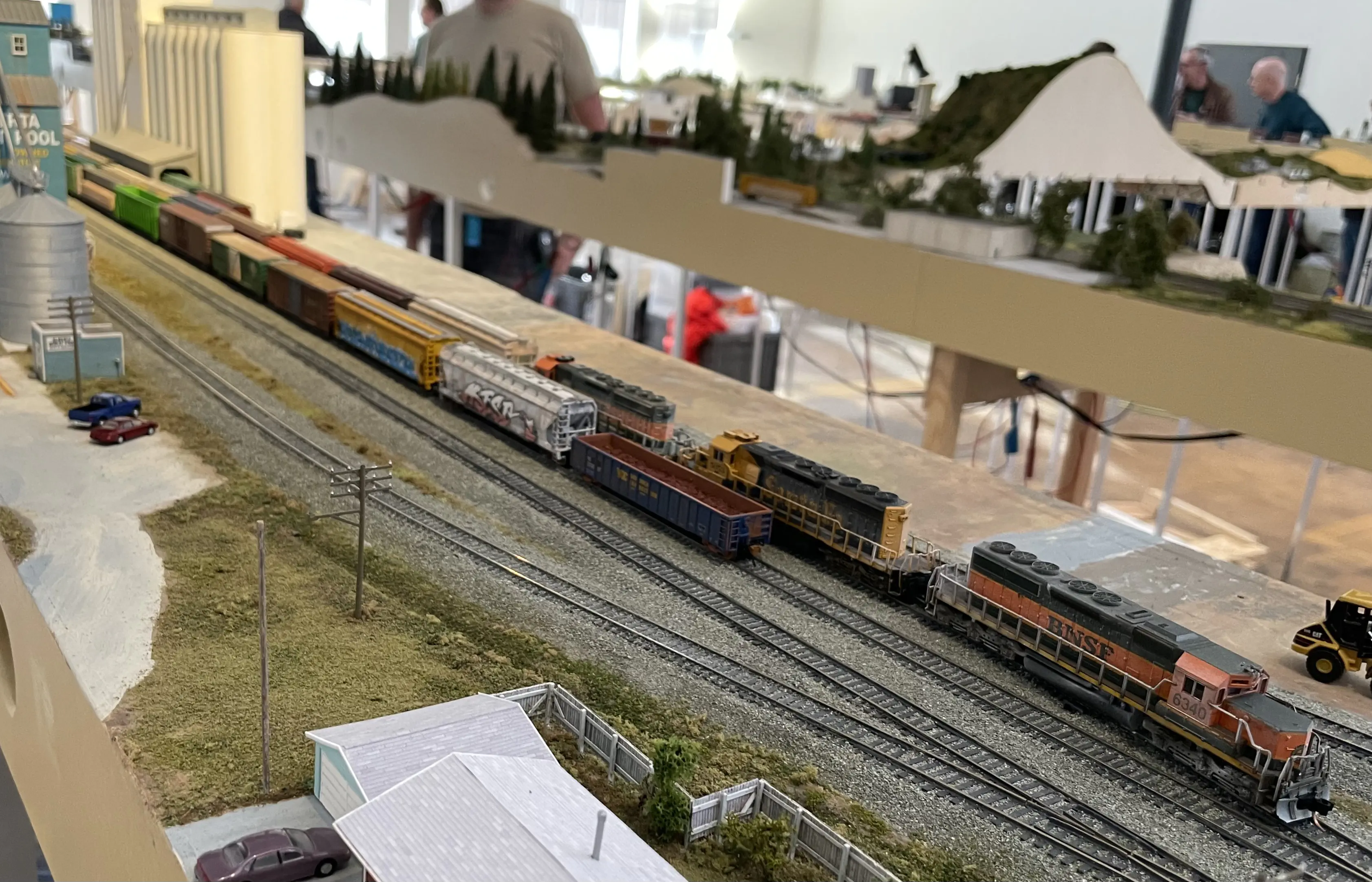

The Layout

Never the same layout. For every modular meeting, we plan a new layout. The layout is planned to match all the given constraints, like the room, the attendees and the available modules, the choosen era. A layout may vary in size, shape and the order of modules. The modular layouts may fill a small room or a large venue. It is never the same but it is always made for operations.

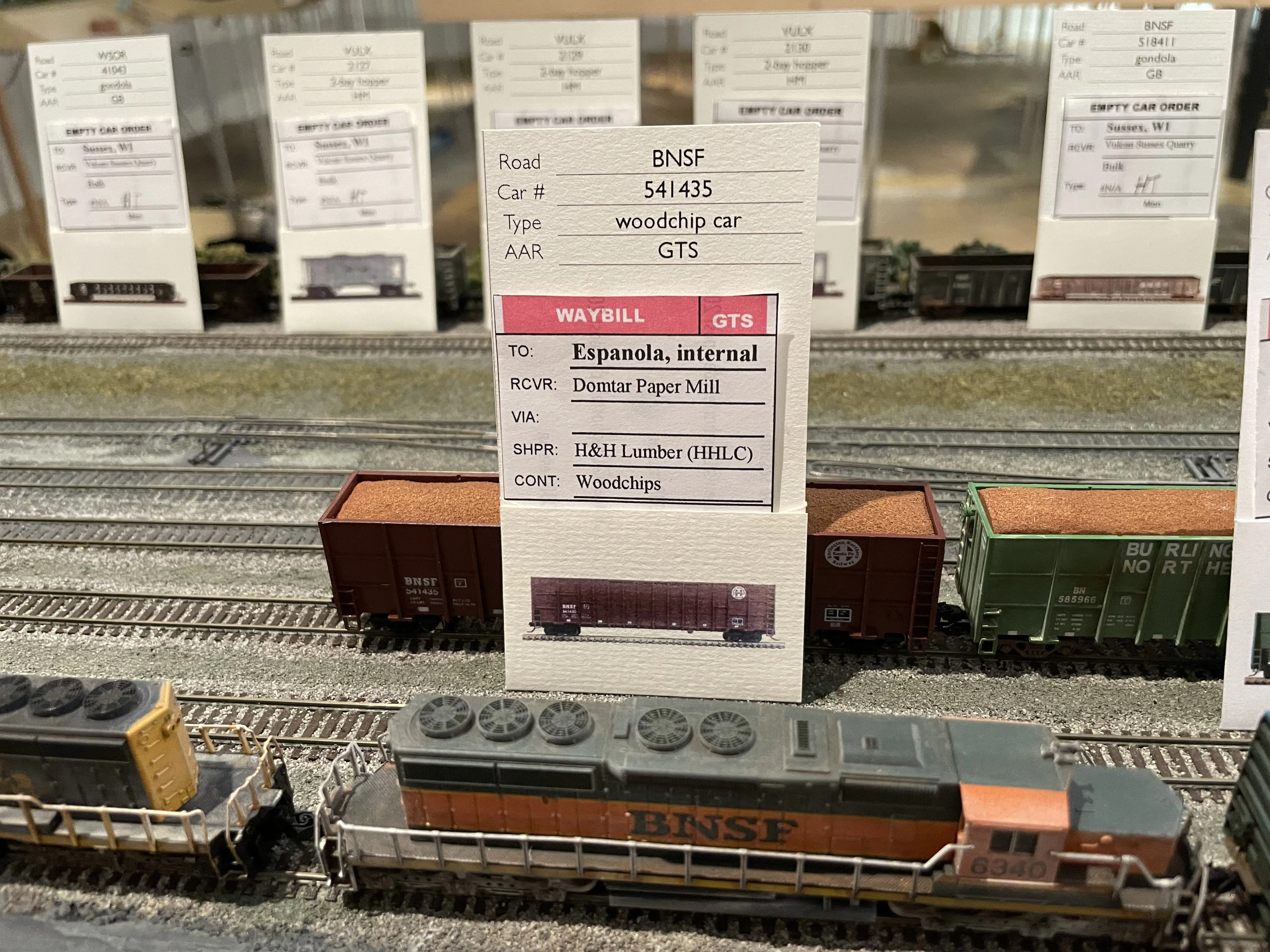

Car routing with Car-Card and Waybill

For every car used during a meeting needs a car card. The owner of an industry that is used in the layout, has to bring the required waybills for all his inbound and outbound traffic. Most industries have varying traffic during the week days which are represented by the operating sessions. Thus there has to be a complete set of waybills for the whole week.

When the trains for an operating session are staged, the waybills are distributed to incoming trains, which are setup in the staging yards. Depending of the operationinal concept for the meeting, this may only include manifest trains but it may also including local trains.

Outbound traffic is routed according to the colors used on either the car card for empties or on the waybill for loaded cars.

Sessions

Each session represents one day of the week. Usually the first session is a monday. After all operations for the session have been completed and the outbound trains have arrived at the staging yards, a session-turnover happens. This includes pulling all waybills for inbound trains, turning waybills for empty cars making them loaded cars and staging the new inbound trains in the staging yards. Once all steps are complete, the next session may start.

Staging

The staging yards simulate the connection to the outer world, so all inbound cars enter the layout through one of the staging yards and empties and outbound loads leave the cars via the staging yards. Before a session can start, all inbound cars, which are either Empty Car Orders our Inbound Loads are setup in one of the manifests at the staging yards.

Ahead of time we choose which colors are destined to which staging yard. A layout will at least have one staging yard but it may also have three or more. The color assignments are usually made to balance the traffic between the yards in order not to overwhelm a single staging yard or route. For small staging yards it might be appropriate to assign a color which is known for a low traffic volume, which us usally blue, black or grey.

Manifest Trains

All traffic that is not directloy routed from a staging yard to an industry is handled by a manifest. Each manifest starts at a staging yard and travels a certain route through the layout and most of the times ends in a destination staging yard.

Depending on the layout and the operational concept manifest might also return to the same staging yard, after turning at their given destination.

Most manifests do involve little or no switching, except for dropping and picking up blocks of cars at yards on their route. This is often supported by a local switcher and allows a short break for the crew of the manifest.

In a typical session, the manifests are the longest trains and may contain from 15 to 70 cars each. We usuall prefer to limit the length of our trains as excess length makes handling these trains in the yards quite challenging.

Local Trains

Typically industries are served by local freigth trains. These may start at a staging yard or in a yard on the layout. A local works on a part of the layout and serves all industries in his district.

A typical local would start at a yard, either staging or on layout. After departing the yard it switches all industries along its way. After reaching the furthes point of its route, it would turn and return to its origin. Some locals run in one direction only but most often they are operated as a turn.

A local turn has the advantage, that it may ignore all facing spots and switch them after turning, when they are trailing spots. Thus it is usually not required to do any runaround moves, except the one for turning the train. This makes the operations more efficient and in my personal opinion more enjoyable.

Passenger Service

Depending on the chosen era, modules and available rolling stock, some passenger service might be included in the traffic. Most passenger trains are simple through trains or turns. Sometimes a little switching might be included, to pickup or setout some head end equipment, like express freight or mail cars.

Internal Freight

Making the deals for internal freights sometimes feels like shoping on a basar. In our chapter the term internal freight is used for any loaded cars that travel from one industry to another within the layout. Most loads are inbound loads from the outer world - staging yard - and the outbound traffic from the industries to staging yards. That`s a simple procedure, as it requires very little planning and coordination between the owners of the modules.

Internal freight is handled slightly different. We use the typical four-step-routine, like any other traffic. So at least four steps are required for a car in internal freight service.

- Step: A car is staged in the inbound traffic, according to an Empty Car Order

- Step: Once a car has reached its first destination, the waybill is turned to show its new destionation

- Step: A car is routed to its second destination

- Step: After the car has arrived, the waybill is pulled during the session-turnover and the empty car is routed to a corresponding staging yard

Depending of the car routing during for a specific meeting and layout, each step may require more than one session.

Traffic Management

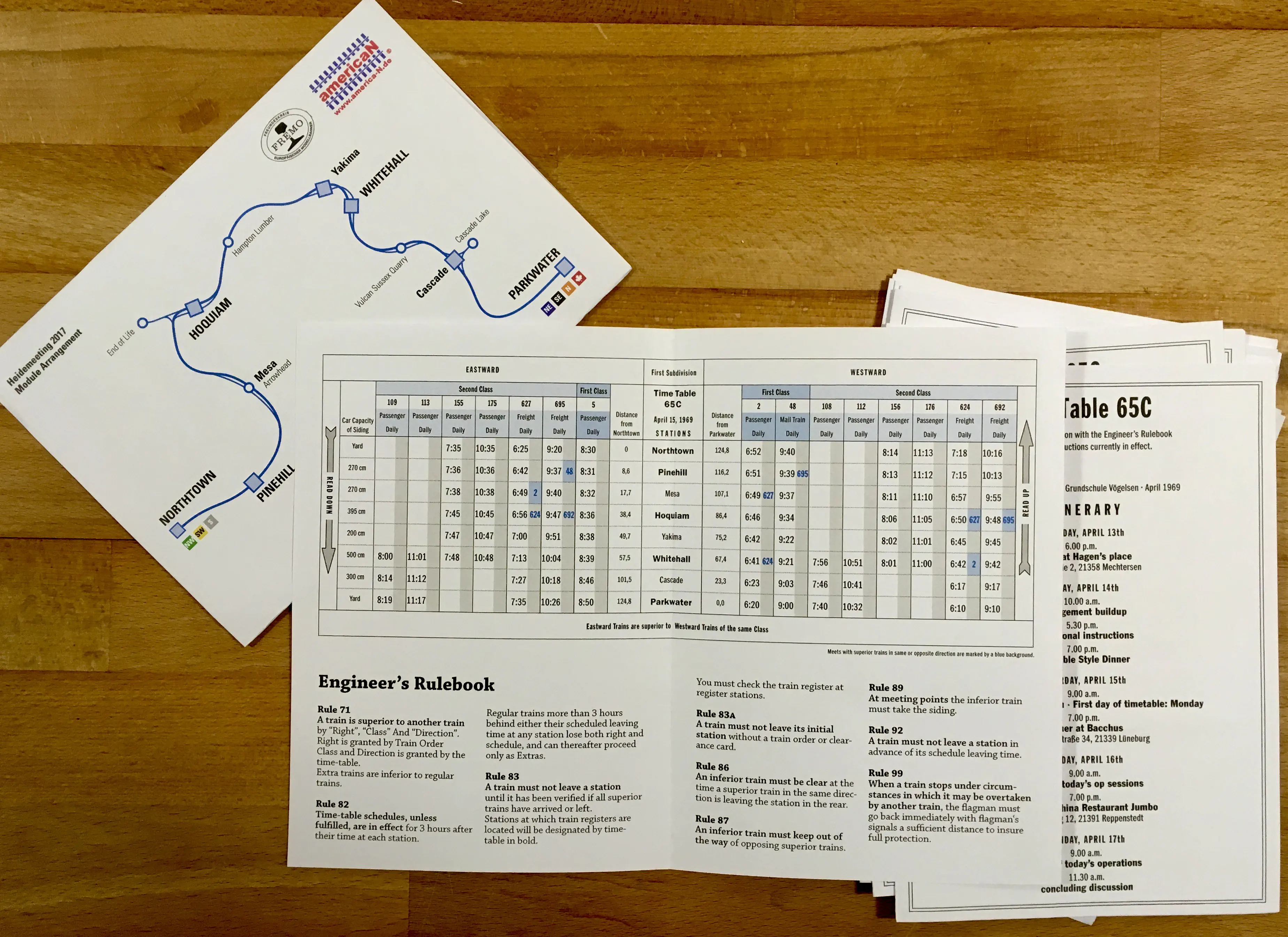

TT&TO - Time Table and Train order

When the layout and the choosen era support TT&TO, we may choose to operate in this fashion. To give the crews the necessary information, they are handed a time table, which usually includes a diagram of the layout and the rules we came up with.

For our operations whe only need a very basic set of rules, thus we took some liberties and removed all the clutter and reduced the ruleset to the very minimum to ensure safe operations. Our timetabler is calculated without a fastclock, so we altered the times so a reasonable amount.

In This case most trains are assigned to the timetable and thus require no or very little management by the dispatcher. Only extras or trains that are late explicitly need a clearance by the dispatcher. The planning of such a meeting requires more effort and a certain type of modules, which are used within the mainline to support meets.

This mode of operation requires more thinking and planing by the train crews, as the have to decide by them self wether it is safe to leave a station or let another train pass.

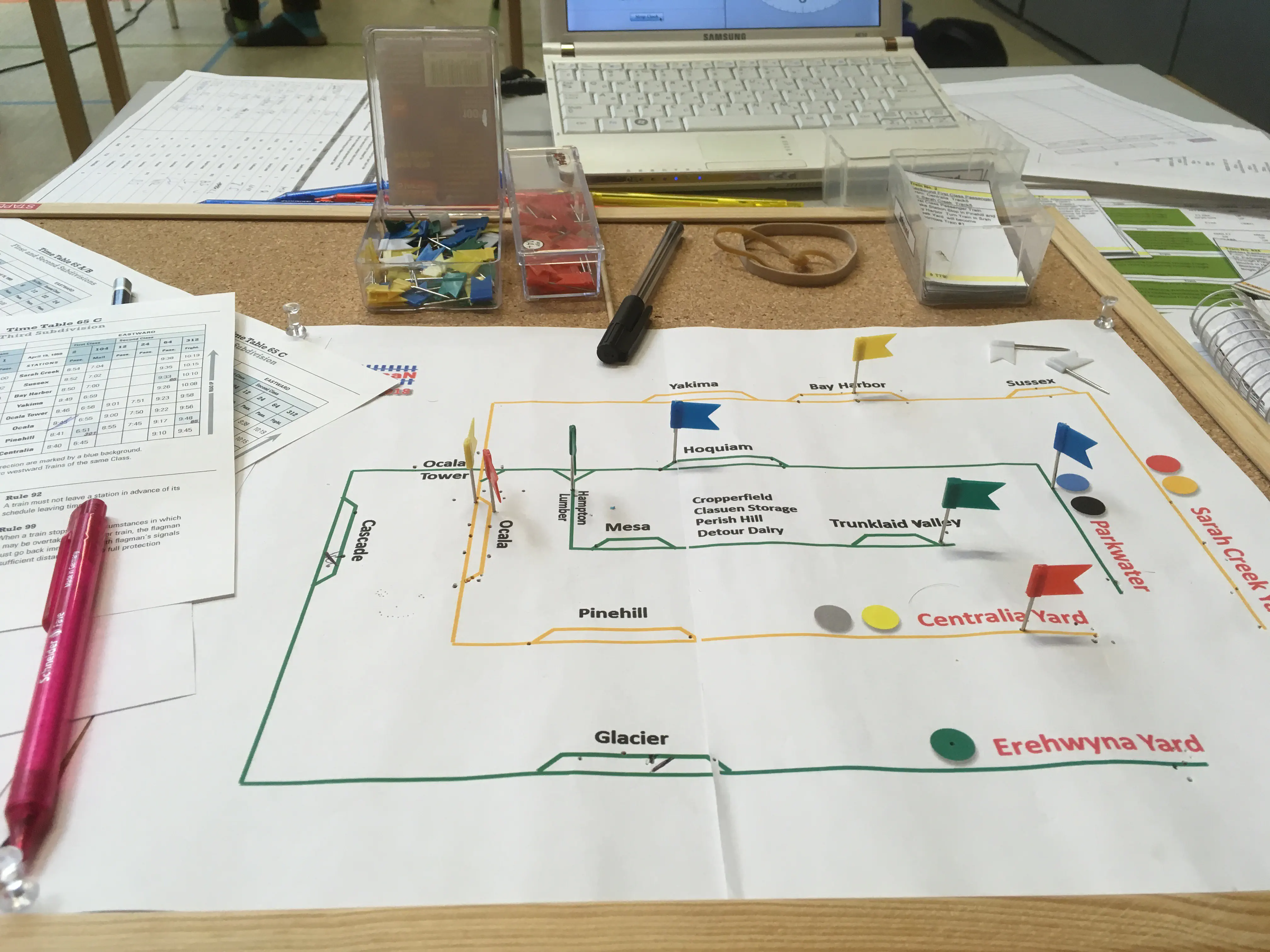

DTWC - Dispatcher Track Warrant Control

Most modules do not include any singalling, so we rely on a dispatcher to prevent any unintend contacts between the trains.

Every train crew and the dispatcher is equipped with a radio. For every move on the manged routes the crew has to contact the dispatcher and request a permission for a certain stretch of the line. A few years ago we started using a custom form for our track warrants. We call it trackwarrant light. It reduces the amount of radio traffic and paperwork for everyone. Its basically a table, which is used to write down the destination you are allowed for - “Check box 2” and it allows to note a condtion for wait-for train-number define a meeting. If required you can simply use multiple lines.

This minimized track warrant is not as close to the prototype as the prevoius one, but it massively reduces the time required to issue a TW and thus enables the crews to reach the dispatcher without waiting forever. As someone who tried to reach the dispatcher for more than one hour to get the next track warrant, I do like this a lot.

The Jobs

Every train is a single job. Some jobs last the whole session, for example the dispatcher and yard masters. Some jobs last less than an hour, a typical example are through trains or passenger trains. These require less or no switching. A local train may take the whole session, depending on the size of the layout, the concept and the number of industries and spots it serves.

Some jobs depend on others, for instance if there is a scheduled meet or if it requires cars that have to be delivered by another train. Most locals are quite self contained and may only require the support a yard to begin and to finish, but in the meanwhile they work on their own. So there is a wide variety of tasks.

Most of the time, we try to create enough jobs for all participants, so everzone can run a train at the same time. We had some meetings where it was absolutely required for all of us to work their train, thus we only took breaks together. That was a very satisfying experience, as noone had to wait for his next assigmnent.