Building Sussex 2: Trackwork and Electrics

By hagen

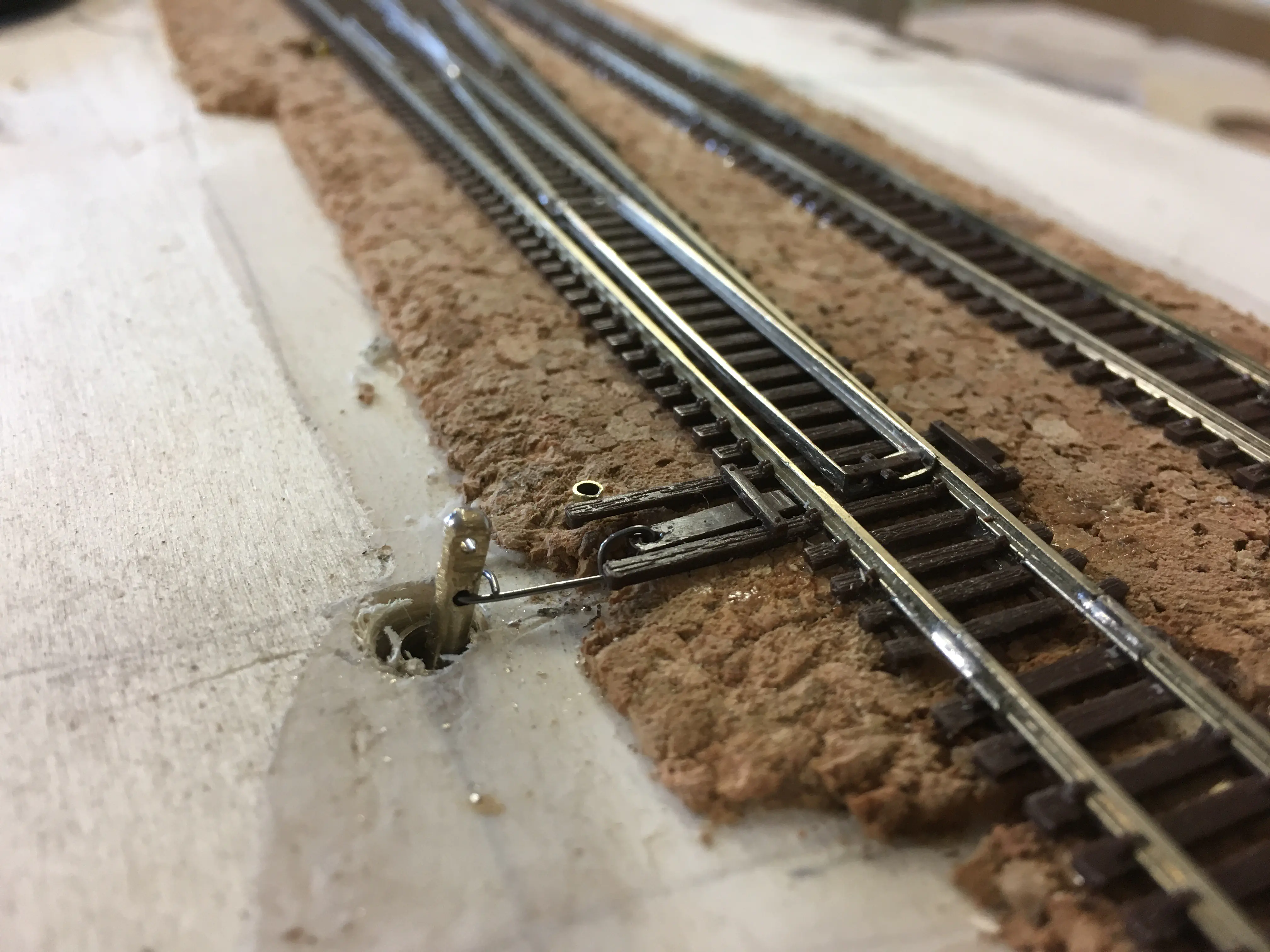

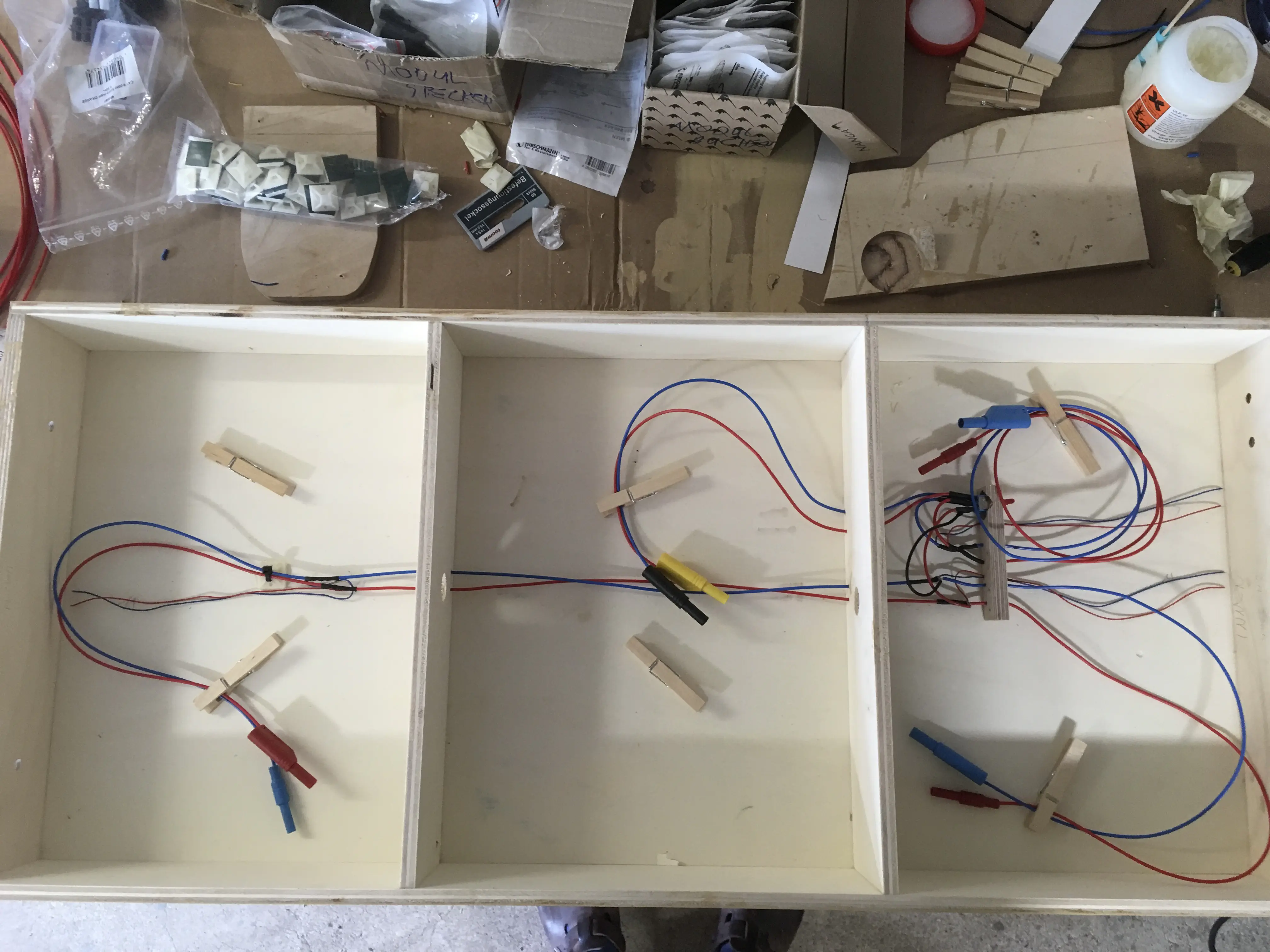

After completing the woodwork, I installed the track on the segments for my new module. For an easy setup I installed positioning dowels between all segments before laying the track.

When laying track over a module connection I use a 1 mm sheet of styrene as spacer between the segments. My cut might go slightly wrong and this spacer gives me enough safety distance to make cuts between the modules without leaving an unwanted gap. Later the ends of the rails are filed so they won’t extend the end of the module and are less prone to damage during transport.

Operating Turnouts

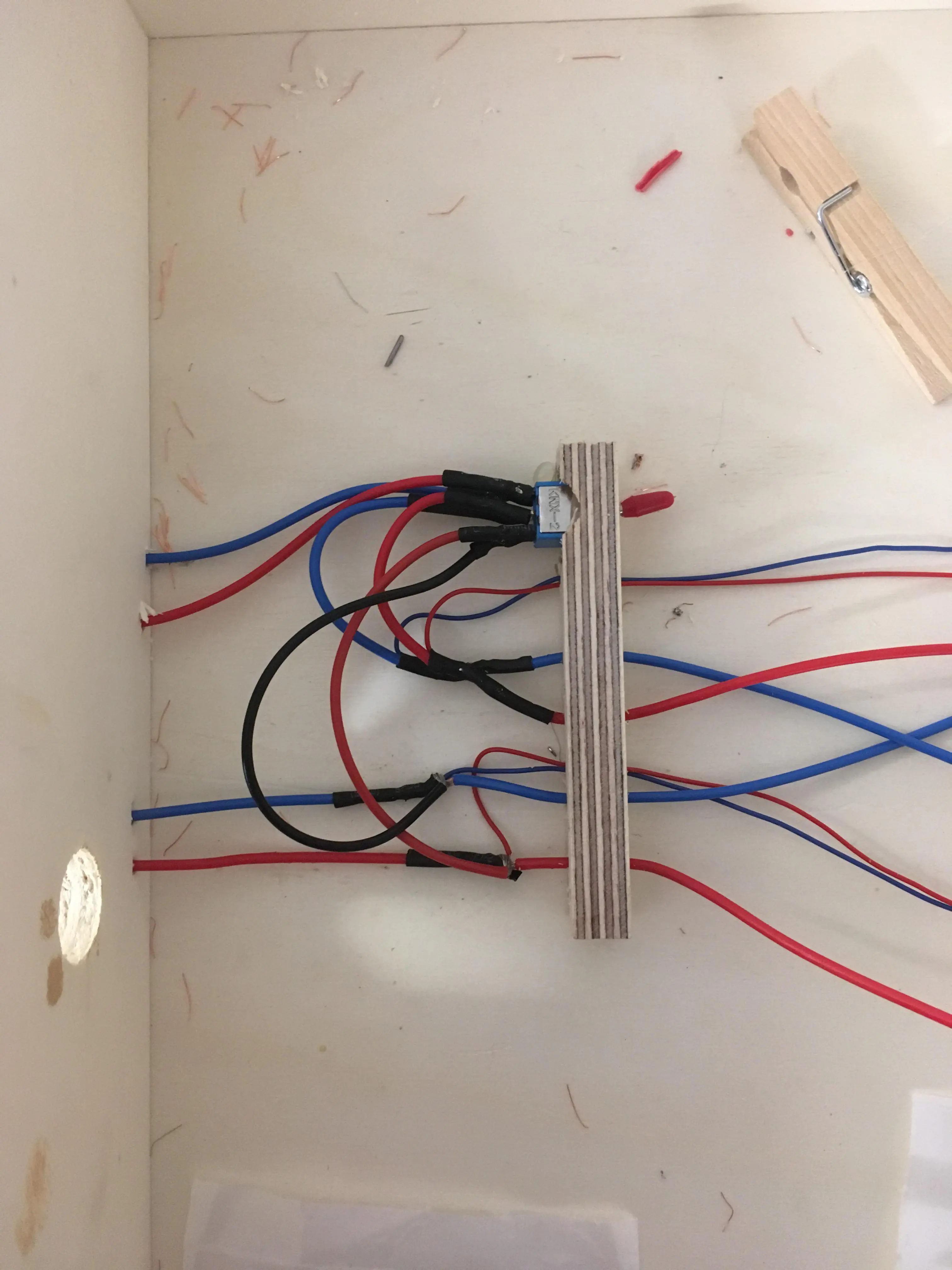

This module as three turnouts. In one place the scenery did not permit to install the turnout mechanic under the module. I did not want to build a complicated mechanism and I wanted all turnouts on the module to be operated the same way. Thus I choose to install the polarity switches in the surface module. Operates will directly use the switch to lay the turnout and set the polarity of the frog at the same time. This approach is stupidly simple and does not look as elegant as other solutions but it works and solves the problem.Wiring for signals

In the prototype the safety of the mainline is protected against the spur with a signal. I do not plan to add the signal right now, but I wanted to be prepared. Thus I wired main line and the spur separately. This ads more connectors but makes the module future proof. I added a toggle switch to select between feeding from mainline power or via a separate connection: The black and yellow plugs.Read more about the progress in my Building-Sussex Series.